TAPPI T 829 Test Fixture

TAPPI T 829 describes a qualitative method for evaluating the relative quality of scores in corrugated containers

Please Contact With Us For More Information

TAPPI T 829 Score Quality Test

TAPPI T 829 describes a qualitative method for evaluating the relative quality of scores in corrugated containers

Apparatus

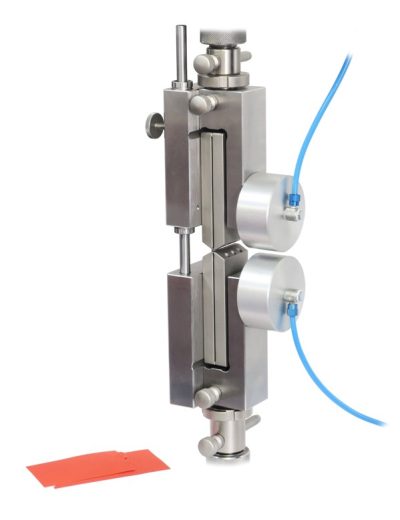

1 3.1 A device capable not only of applying a force at a constant speed of 0.8 mm/sec (0.031 in./sec), but also allowing a minimum of 12.7 mm (0.5 in.) travel,

or a sufficient amount of travel to ensure a maximum 90° bend of the test sample.

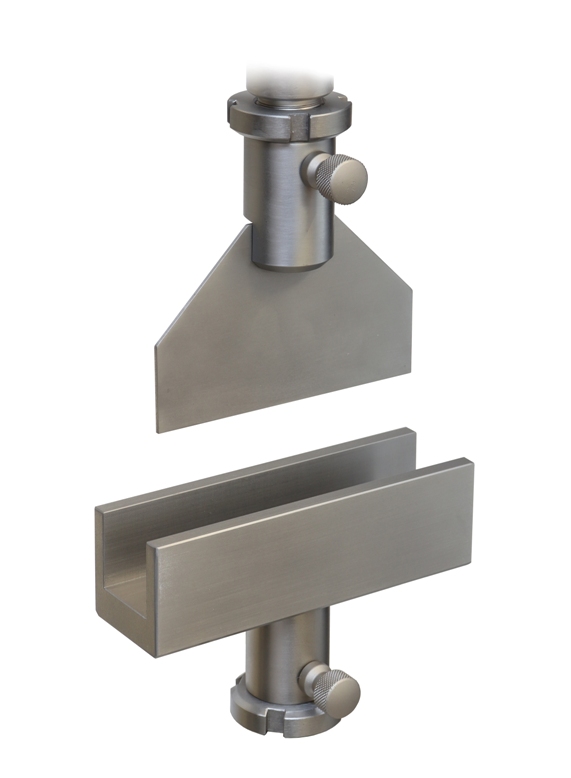

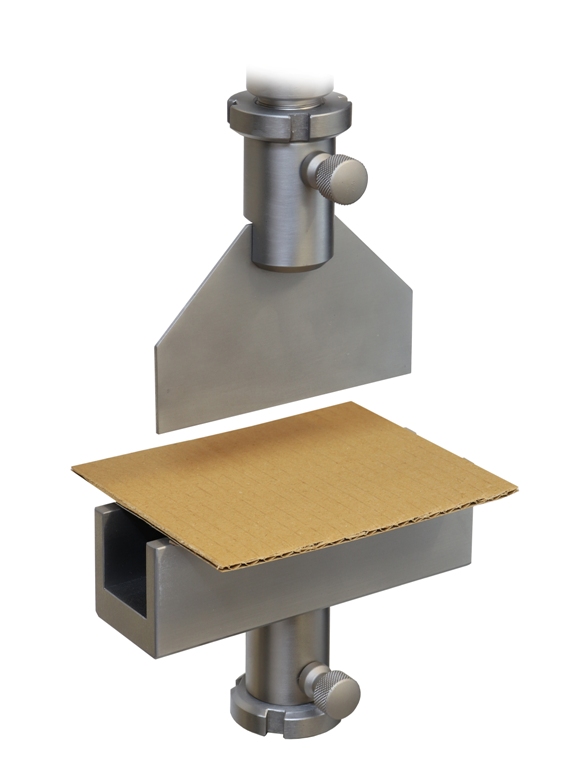

3.1.1 A U-shaped channel having an internal width of 27 mm (1.063 in.), an internal depth of 22 mm (0.87 in.), a wall thickness of 1.6 mm (0.063 in.), and an

edge radius of 0.25 mm (0.01 in.), with an overall length of 102 mm (4.0 in.) (see Fig. 1).

3.1.2 A pressure bar having a thickness of 1.6 mm (0.063 in.), and an edge radius of 0.13 mm (0.005 in.), with an overall length of 102 mm (4.0 in.) (see Fig. 1).

3.2 Force gauge or load cell capable of measuring and indicating the applied force to within ± 1% or 2.5N (0.56 lbf) whichever is greater and must have sufficient

capacity so that all readings can be maintained in the middle half of the scale.

3.2.1 Attach the force gauge or load cell to the stationary (nonmoving) member of the device.

*** Before conducting TAPPI T 829 , it is important to read the entire specification. Standards can be obtained from appropriate standard authorities.