TAPPI T 811 Test Fixture

TAPPI T 811 describes procedures for determining the edgewise compressive strength (ECT), perpendicular to the axis of the flutes, of a short column of

single-, double-, or triple-wall corrugated fiberboard .

Please Contact With Us For More Information

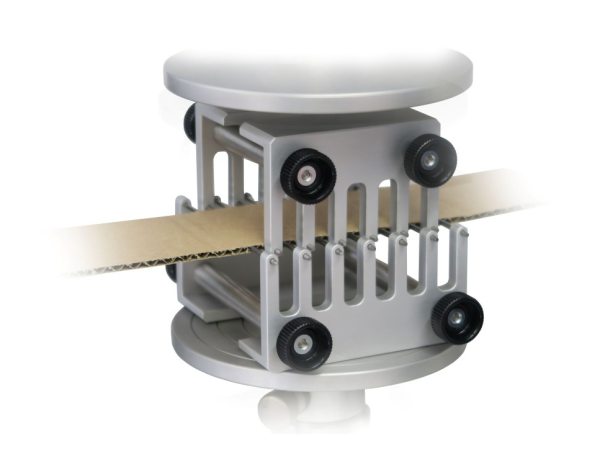

TAPPI T 811 Edgewise Compressive Strength of Corrugated Fiberboard (Short Column Test)

TAPPI T 811 describes procedures for determining the edgewise compressive strength (ECT), perpendicular to the axis of the flutes, of a short column of

single-, double-, or triple-wall corrugated fiberboard .

The method includes procedures for cutting the test specimen, specimen support (waxed edges), and two procedures for applying the compressive force

(constant strain rate, or constant load rate)

TAPPI T 811 – Apparatus

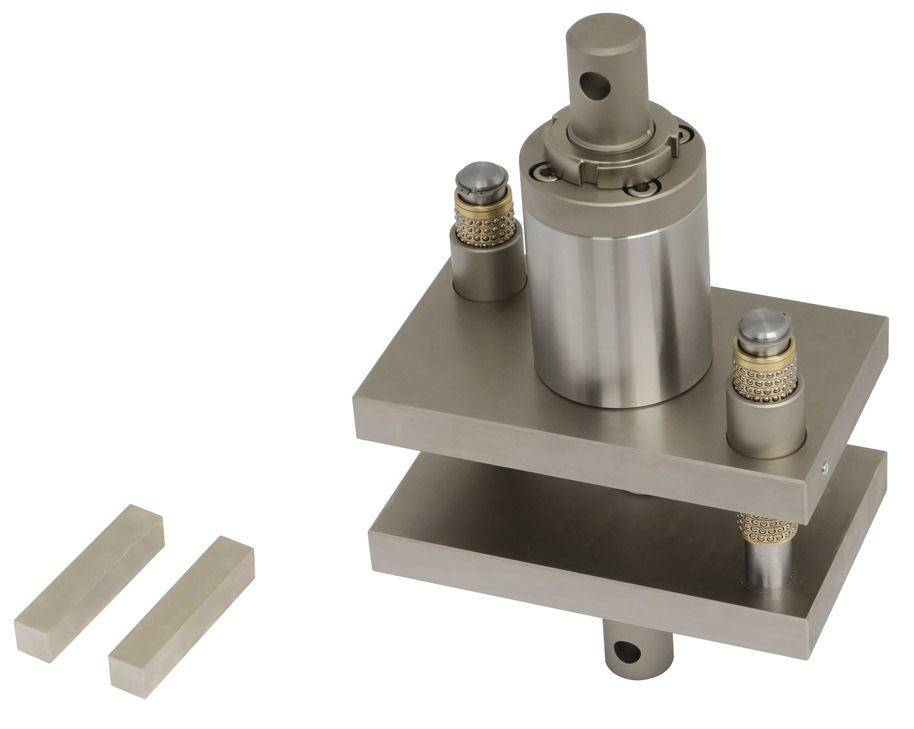

3.1 Compression testing machine1 meeting the requirements of either 3.1.1 or 3.1.2, and 3.1.3, 3.1.4, and 3.1.5. 3.1.1

Rigid Support Compression Tester. Two platens, one rigidly supported and the other driven. Each platen shall have a working area of approximately 100 cm2 (16 in.2 ).

The platens are not to have not more than 0.050 mm (0.002 in.) lateral relative movement, and the rigidly supported platen not more than 0.150 mm (0.006 in.)

movement, perpendicular to the surface, within a load range of 0 to 2224 N (0-500 lbf).

Within the specimen contact area, each platen shall be flat within 0.0025 mm (0.0001 in.) of the mean platen surface, and the platens shall remain parallel to

each other within 1 part in 2000 throughout the test (6).

3.1.1.1 Within a range of platen separations necessary to cause compressive failure of the test specimen, and within a load range of 0 to 2224 N (0-500 lbf), the

speed of the driven platen shall be controllable at 12.5 ± 0.25 mm (0.5 ± 0.01 in.) per minute.

(For convenience, the test machine should be capable of rapid return and automatic, settable positioning).

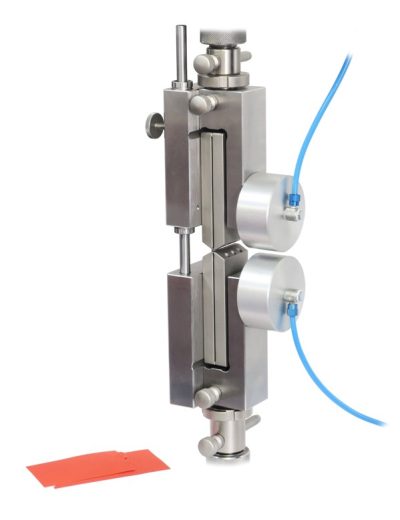

3.1.2 Flexible Beam Compression Tester.

Two platens, one flexible beam supported and the other driven.

Each platen shall have a working area of approximately 100 cm2 (16 in.2 ). Within the specimen contact area, each platen shall be flat within 0.0025 mm (0.0001 in.) of

the mean platen surface, and the platens shall remain parallel to each other within 1 part in 2000 throughout the test.

The platens are required to have not more than 0.050 mm (0.002 in.) lateral relative movement.

3.1.2.1 Within a range of platen separations necessary to cause compressive failure of the test specimen, and within a load range of 0 to 2224 N (0-500 lbf),

the speed of the driven platen shall be controlled so that the rate of force increase (without considering specimen deformation) is 111 ± 22 N/s (25 ± 5 lbf/s) (6).

3.1.3 The driven platen shall be moveable to achieve an initial platen separation of at least 60 mm (2.36 in.).

3.1.4 The tester shall have a capacity of at least 2224 N (500 lbf).

3.1.5 The tester shall have a means for measuring and indicating the maximum load sustained by the test specimen with an accuracy of 0.5% or better between

a measured load of 440 N (100 lb) and the equipment’s maximum load.

Below this measured load, the accuracy shall be 2.2 N (0.5 lbf), or better whichever is greater

*** Before conducting TAPPI T 811 , it is important to read the entire specification. Standards can be obtained from appropriate standard authorities.