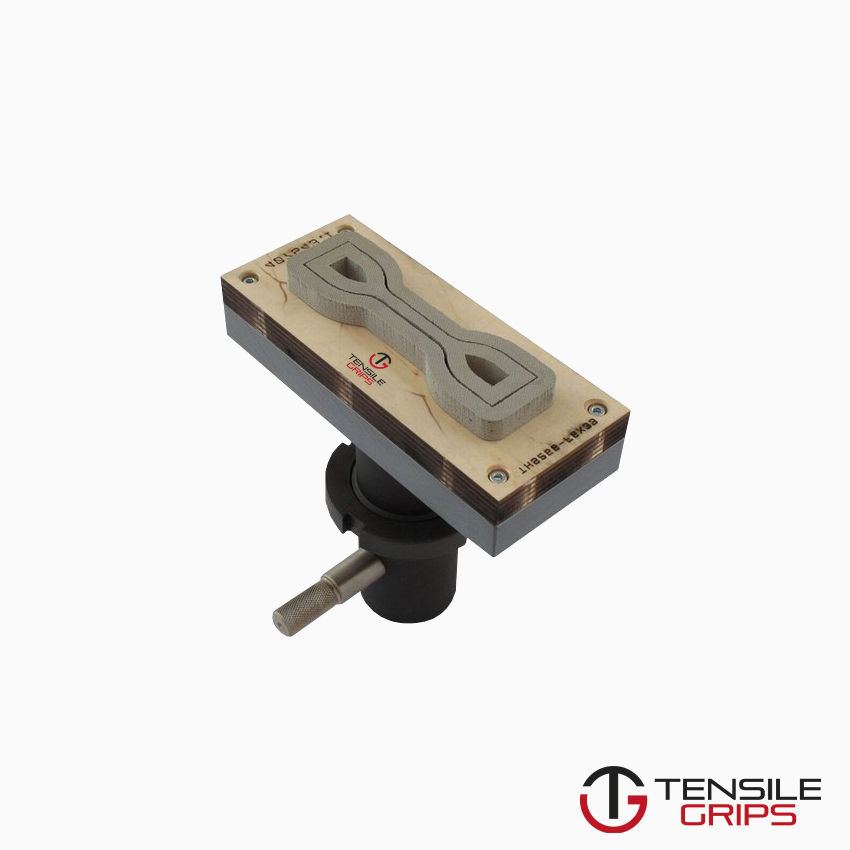

ISO 527-2 Test Fixture

ISO 527-2 specifies the test conditions for determining the tensile properties of moulding and extrusion plastics, based upon the general principles given in ISO 527‑1.

Please Contact With Us For More Information

ISO 527-2 Tensile Testing For Plastics

ISO 527-2 specifies the test conditions for determining the tensile properties of moulding and extrusion plastics, based upon the general principles given in ISO 527‑1.

ISO 527-2 is a popular and extremely important test method. By measuring the force required to pull a test specimen to its breaking point, several material properties

can be determined.

This data enables both product design engineers and quality managers to accurately predict the performance of their products in end-use applications.

This information is critical for developing new products ensuring compliance to industry or government standards, improving manufacturing and reducing production costs.

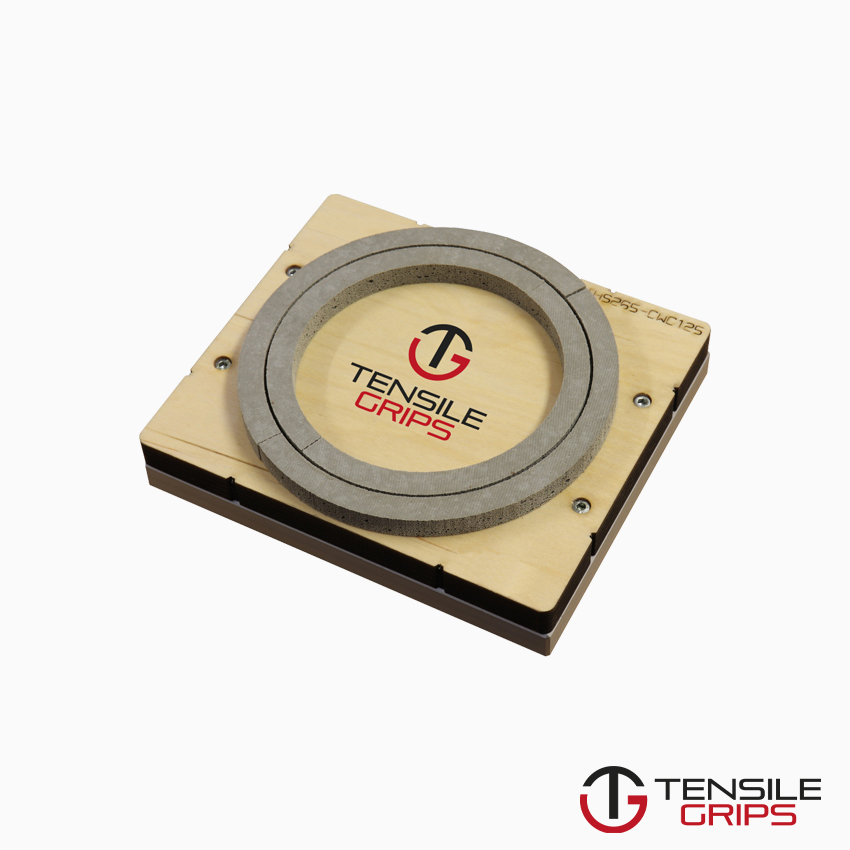

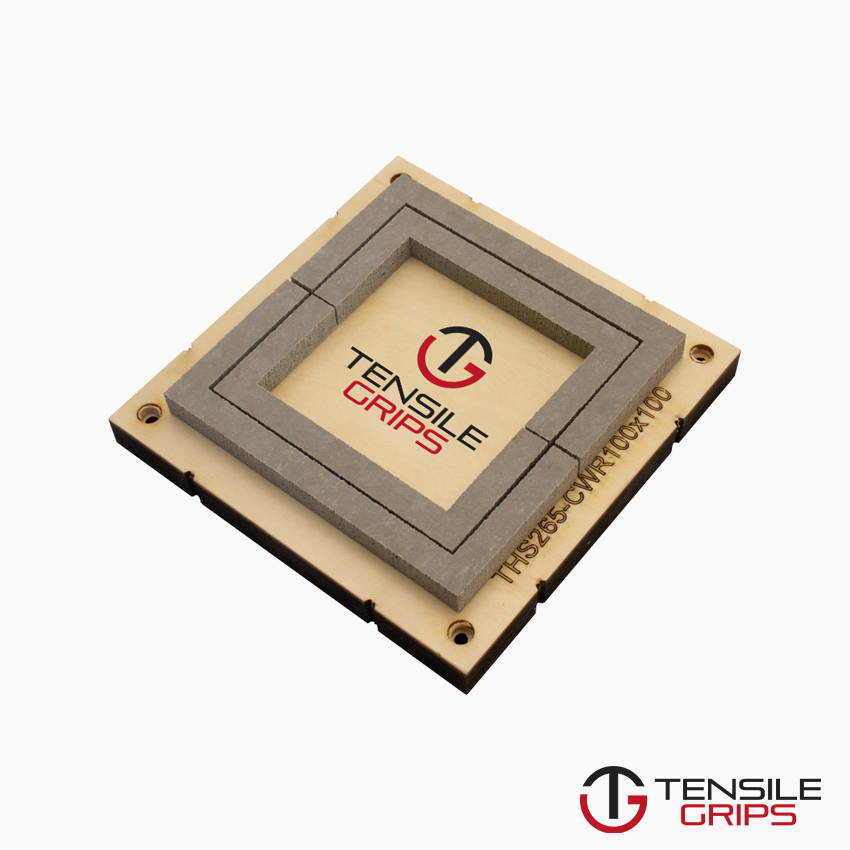

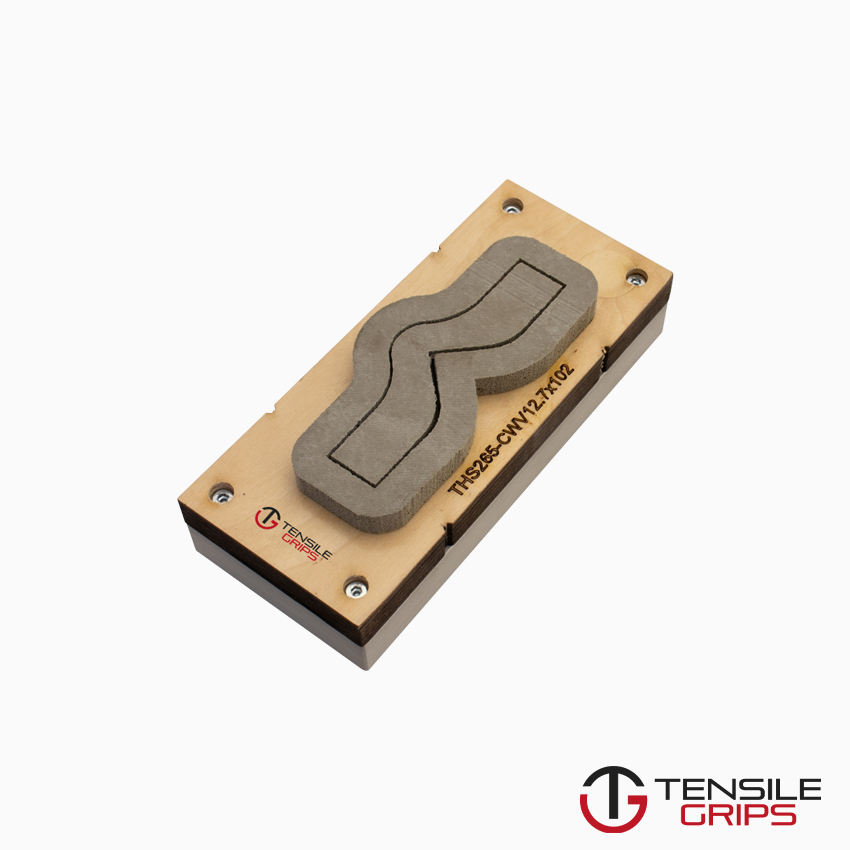

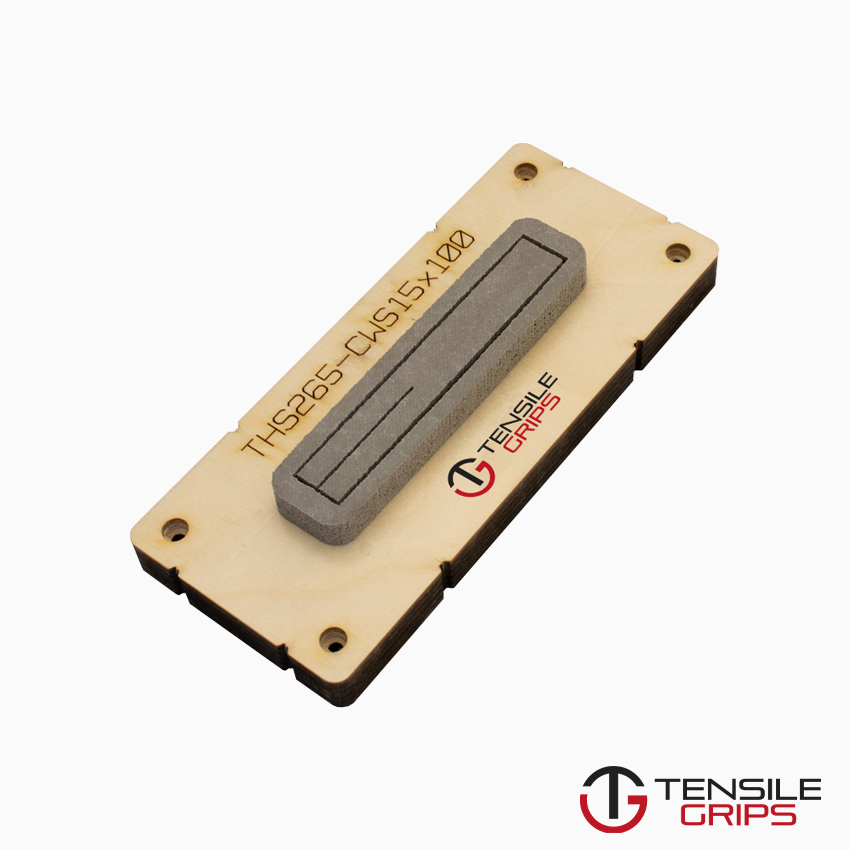

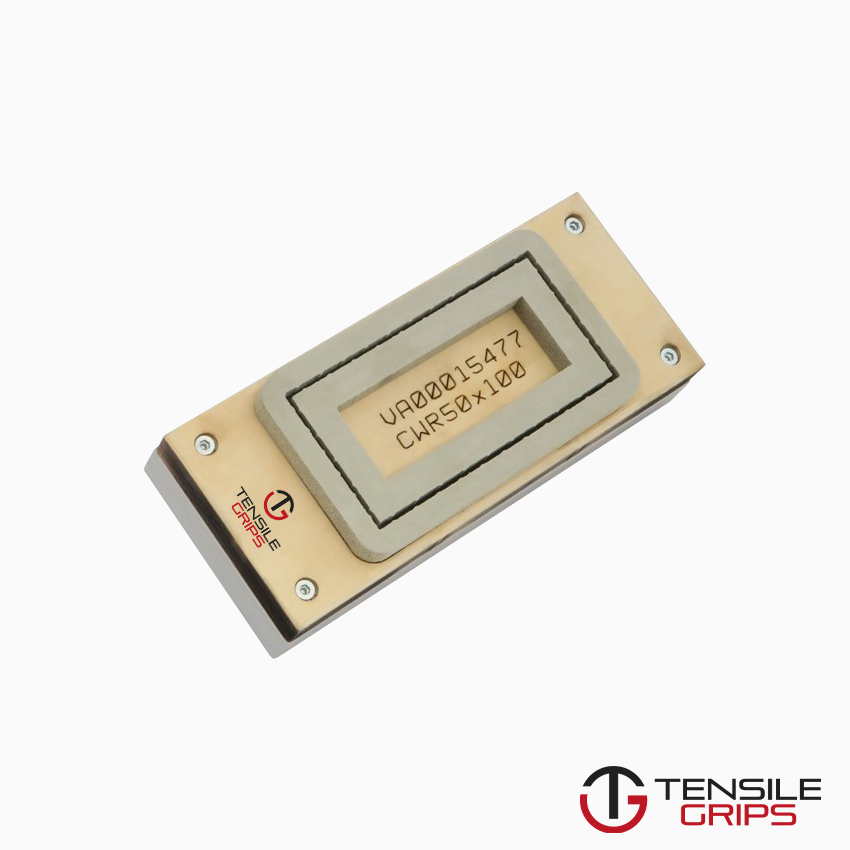

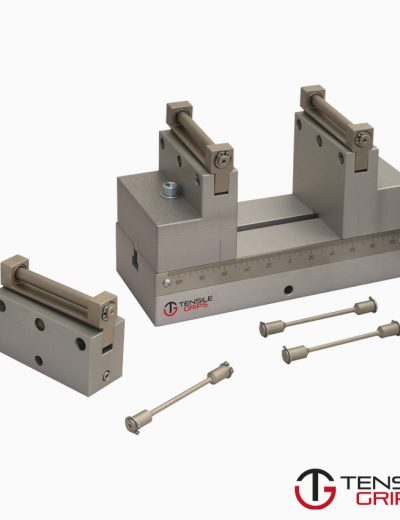

To perform these tensile tests, the “dumbbell-shaped” test specimens are placed in the grips of a universal testing machine (UTM) and subjected to controlled tension until

they fail.

Test speeds vary by specimen type to achieve a 1%/min strain rate, and an extensometer is used to measure specimen parameters.

The resulting tensile test data is used to report material properties such as stress, strain, tensile modulus and Poisson’s ratio.

ISO 527-2 is very similar to ASTM D638, with one key exception being analysis of the non-linear portion of a material’s stress-strain curve.

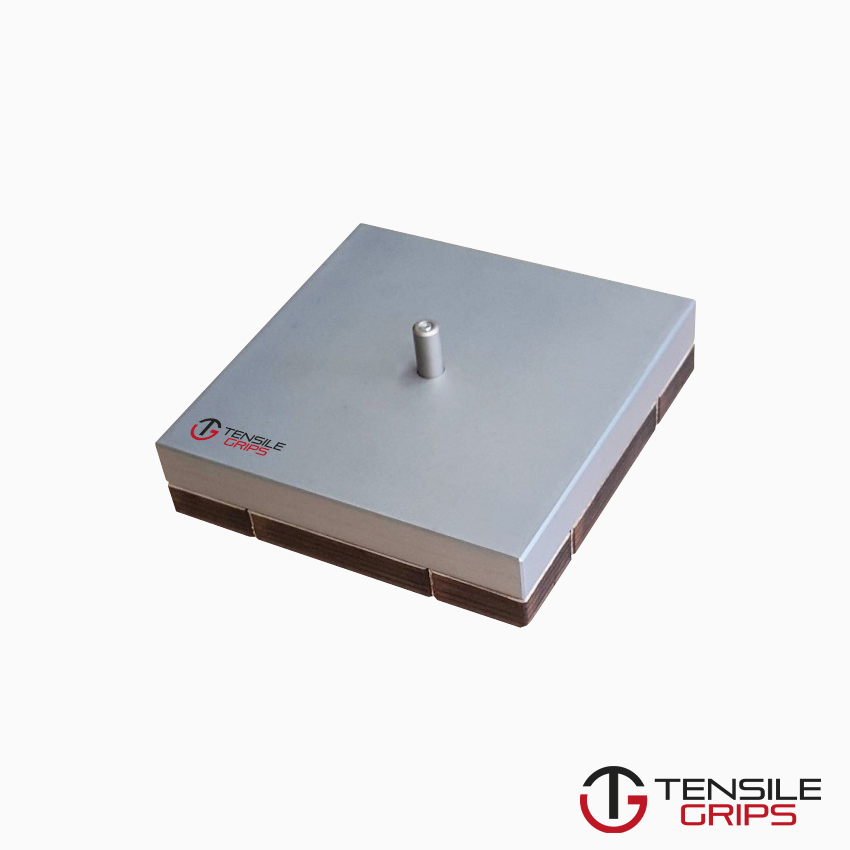

Universal testing machines are ideal for tensile testing of plastics per ISO 527-2

*** Before conducting ISO 527-2 , it is important to read the entire specification. Standards can be obtained from appropriate standard authorities.