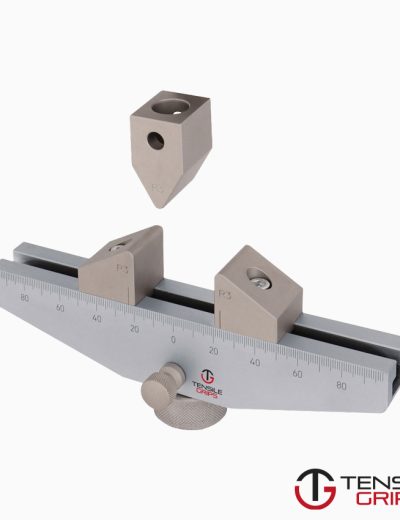

ISO 20482 Test Fixture

ISO 20482 specifies a standard test method for determining the ability of metallic sheets and strips having a thickness from 0,1 mm up to 2 mm and a width of

90 mm or greater to undergo plastic deformation in stretch forming.

Please Contact With Us For More Information

ISO 20482 Metallic Materials — Sheet and Strip — Erichsen Cupping Test

ISO 20482 specifies a standard test method for determining the ability of metallic sheets and strips having a thickness from 0,1 mm up to 2 mm and a width of

90 mm or greater to undergo plastic deformation in stretch forming.

For materials that are thicker and when only narrower strips are available, tools of specified dimensions are provided, in which case subscripts are used

ISO 20482 – Testing Equipment

The test shall be carried out on a machine equipped with a die, punch and blank holder with dimensions and tolerances.

The construction of the machine shall be such that it is possible to observe the outside of the test piece during the test in order to be able to determine the instant

when a through crack appears.

NOTE : In general, the commencement of rupture is accompanied by a drop in the force sustained by the test piece and sometimes by perceptible noise.

The machine shall be equipped with a gauge for measuring the movement of the punch with a scale division of 0,1 mm.

The die, the blank holder and the punch shall be sufficiently rigid not to deform during the test.

The Vickers hardness of working surfaces of the die, the blank holder and the punch shall be at least 750 HV 30.

The punch shall not turn during the test.

The working surface of the punch shall be spherical and polished. The mean value of roughness Ra as defined in ISO 4287 shall be ⩽ 0,4 µm.

The distance from the axis of the die to the centre of the spherical part of the punch shall be less than 0,1 mm throughout its range of movement in use.

The surfaces of the blank holder and of the die in contact with the test piece shall be plane and perpendicular to the axis of movement of the punch.

The forming die shall be self-aligning to the (fixed) blank holder.

The machine shall ensure that the test piece is held with a constant holding force of approximately 10 kN.

Measurement of the movement of the punch takes place from the point where it initially touches the surface of the test piece.

*** Before conducting ISO 20482 , it is important to read the entire specification. Standards can be obtained from appropriate standard authorities.