EN ISO 14916 Test Fixture

EN ISO 14916 specifies the procedure to determine the tensile adhesive strength of thermally sprayed coatings under tension in the direction normal to the

surface of the coating by applying a tensile test.

Please Contact With Us For More Information

EN ISO 14916 – Thermal Spraying – Determination of Tensile Adhesive Strength

EN ISO 14916 specifies the procedure to determine the tensile adhesive strength of thermally sprayed coatings under tension in the direction normal to the

surface of the coating by applying a tensile test.

By using this procedure, comparability of the test results is ensured.

The test is intended to determine the tensile adhesive strength between the thermally sprayed coating and the substrate material or between the bond and top

coat and/or of the cohesive strength of the related coat of the coating system.

In some cases, thermally sprayed coatings might have more than two layers.

The method specified in this document applies also to determine the tensile adhesive strength between the interfaces of different layers in a coating system which

consists of more than two layers.

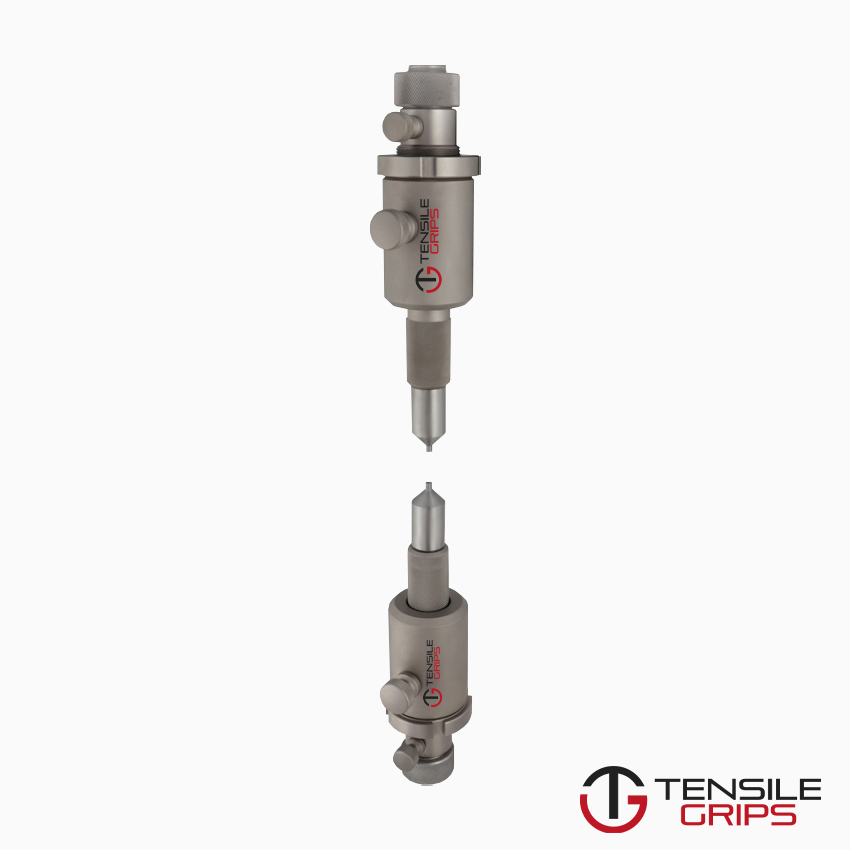

EN ISO 14916 – Equipment for Testing and Measuring and Auxiliary Equipment

Test instruments A tensile testing machine according to ISO 7500-1, class 1, with a suitable clamping system shall be used, which ensures clamping and loading

of the specimens through the centre line following no bending and torsion moments.

Measurement Instrument

Measurements can be carried out, when preparing the loading block and test specimens, using measurement instruments in accordance with standard commercial practices.

Recommendations and examples for special gauges to measure the concentricity and parallelism of specimens with a 25,0 mm diameter are given in Annex B.

EN ISO 14916 – Specimen Fixing Device for Bonding of the Tensile Adhesive Specimen

A fixing apparatus, which keeps the angular and axial deviation of the blocks as low as possible, shall be used in order to glue the loading block to the substrate block

(or to the test disc).

Furthermore, fixing the apparatus shall ensure the application and maintaining of the required contact pressure over the entire gluing process.

NOTE : These objectives can be achieved by using a V-block fixture for centring.

Using the fixture, the coaxial alignment and a sufficient contact pressure can be maintained so that substrate and loading block or two loading blocks and a test disc

can be joined together to form a tensile adhesion specimen with required tolerances.

When applying the required contact pressure (generally low), it shall be ensured that neither bending nor torsion moments affect the bonding joint.

Consideration should be given to defining the value of the required contact pressure.

The contact pressure shall be possibly constant over the entire temperature range during application and hardening of the bonding agent.

If the weight of the top loading block, with respect to the substrate block, is inadequate to create the required load, then loading by means of a spring is recommended.

*** Before conducting EN ISO 14916, it is important to read the entire specification. Standards can be obtained from appropriate standard authorities.