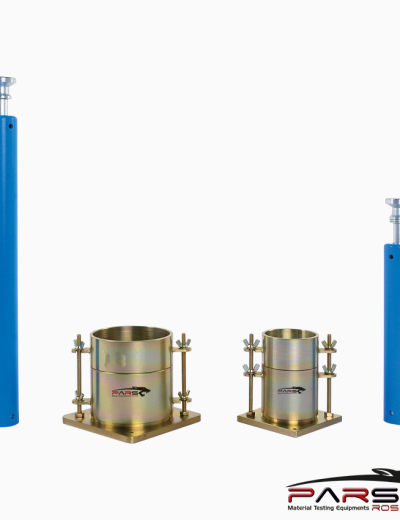

Automatic CBR Loading Machine , 50 Kn

STANDARDS : EN 13286-47; BS 1377:4; ASTM D1883; AASHTO T193; NF P94-078; AS 1289.6.1.1; UNI CNR 10009

Automatic CBR Machine frame is composed of a robust and compact two column frame with adjustable upper crossbeam driven by

an electromechanical ram with a maximum capacity of 50 kN and data acquisition and processing system.

Please Contact With Us For More Information

| Product Code | Product Description |

| PRS-SDCLM5 | Automatic CBR Loading Machine , 50 Kn |

| PRD-SDCLMDLOG | Data Logger with software |

Automatic CBR Loading Machine , 50 Kn

STANDARDS : EN 13286-47; BS 1377:4; ASTM D1883; AASHTO T193; NF P94-078; AS 1289.6.1.1; UNI CNR 10009

ParsRos Automatic CBR Loading Machine frame is composed of a robust and compact two column frame with adjustable upper crossbeam driven by

an electromechanical ram with a maximum capacity of 50 kN and data acquisition and processing system.

The Automatic CBR Loading Machine is designed to load the penetration piston into the soil sample at a constant rate to measure the applied load and piston

penetration at predetermined intervals.

The ram speed can be set between 0.5 mm/min to 5 mm/min by using the Digital Readout Unit. This main feature allows the userto perform tests complying to

BS, EN, ASTM or AASHTO standards with the same machine.

Max movement and mound are controlled by safety switch .cylinder stroke while controlling stability measuring instrument and mound.

Rapid adjustment of the platen is also provided by up and down buttons which are located on the front panel of the digital readout unit.

Default Platen rate is 1mm/min or 1.27 mm/min also maintained under load thanks to an overpowered electric motor.

For safety, the upand down travel of the lower platen is limited the use of limit switches.

The measuring system consists of a 50 kN capacity load cell fitted to the upper cross beam to read stability values and the 25 x 0.01 mm displacement Sensor fitted

to the column.

Features of the Digital Cbr Test Machine

Graphical data on the screen is refreshed simultaneously during test procedure

Capable to Access and use previously done test data

Able to edit test parameters of the testing equipment through Software

Graphical outputs and reports can be saved as a MS Excel worksheet

Maximum flexibility to edit report and graph templates

TFT Graphic Display Data Acquisition and Control Unit

Communication port

Large graphic touch screen display 240 X 128 pixel,

Effective resolution 16 bit ,

Effective sampling rate 40 Hz ,

Features Of the Software

The software continously updates load and displacement until the end of test. When the test is completed,the sharpest slope of the

graph is calculated. The point that this line crosses displacement axis is commented as an offset. This offset is subtracted from the

displacement value at peak point and called as flow.

Customizable User Interface Graphical data on the screen is refreshed simultaneously during test procedure

Capable to Access and use previously done test data

Able to edit test parameters of the testing equipment through Software

Graphical outputs and reports can be saved as a MS Excel worksheetand can be printed out

Maximum Flexibility to edit report and graph templates

Customizable User Interface

The unit is supplied complete with

LCD Control Unit,

50 kN capacity Load Cell,

CBR Penetration Piston and 25 mm Displacement Sensor and Data logger

TECHNICAL SPECIFICATIONS

| Max. vertical span | 645 mm |

| Horizontal span | 275 mm. |

| Cylinder stroke | 60 mm. |

| Power | 220-240 V 1 ph 50 Hz 750 W |

| Dimensions | 520 x 550 x 1450 (h) mm. |

| Weight | 155 Kg |