ASTM E8 Test Fixture

ASTM E8 – This test method covers the tension testing of metallic materials in any form at room temperature, specifically, the methods of determination of

yield strength, yield point elongation, tensile strength, elongation, and reduction of area.

Please Contact With Us For More Information

ASTM E8 – Standard Test Methods for Tension Testing of Metallic Materials

ASTM E8 – Metal Tensile Testing Grips

ASTM E8 – This test method covers the tension testing of metallic materials in any form at room temperature, specifically, the methods of determination of

yield strength, yield point elongation, tensile strength, elongation, and reduction of area.

The gauge lengths for most round specimens are required to be 4D for E8 and 5D for E8M.

The gauge length is the most significant difference between E8 and E8M test specimens.

Test specimens made from powder metallurgy (P/M) materials are exempt from this requirement by industry-wide agreement to keep the pressing of the material

to a specific projected area and density.

Exceptions to the provisions of these test methods may need to be made in individual specifications or test methods for a particular material.

For examples, see Test Methods and Definitions A370 and Test Methods B557, and B557M.

Room temperature shall be considered to be 10 to 38°C [50 to 100°F] unless otherwise specified

ASTM E8 is one of the oldest and most popular tensile tests.

Metals were one of the first materials tested for applications involving the prevention of boiler explosions.

Andrew Carnegie created his fortune because the tensile strength of steel is stronger than iron.

Specified under E8 are numerous calculations and additional measurements such as Poisson’s Ratio which requires transverse strain measurements.

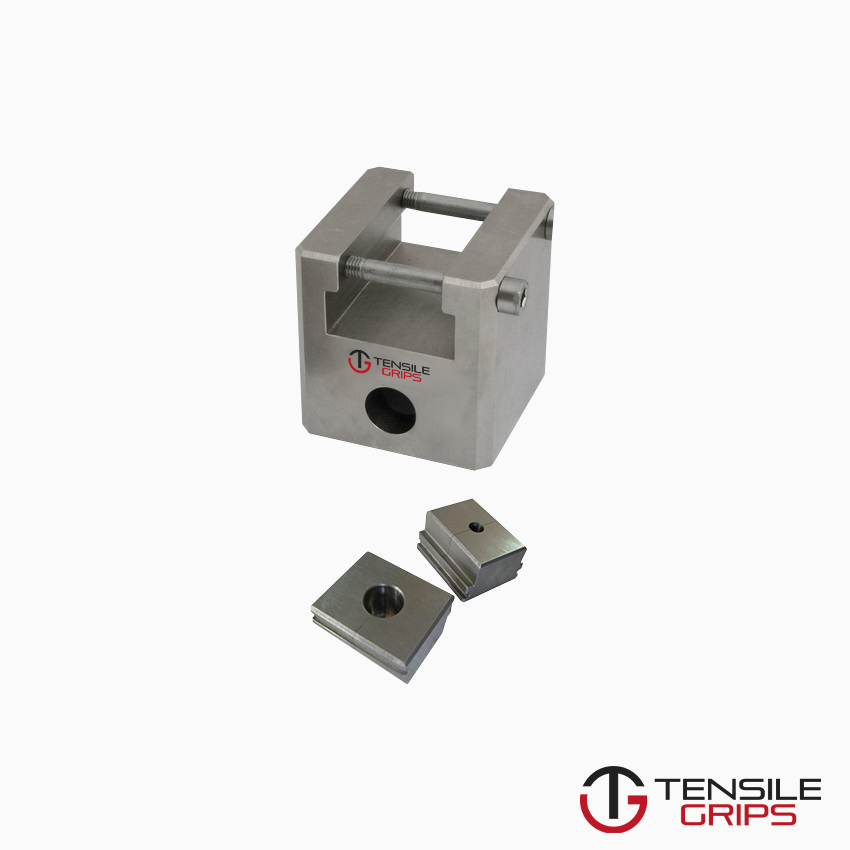

Solution

Grips and fixtures for E8 can vary. For round samples, the end could be butted(square), rounded(tapered), or threaded.

A split collar can be used for the butted ends and a wedge grip with serrated V inserts can be used for the rounded ends.

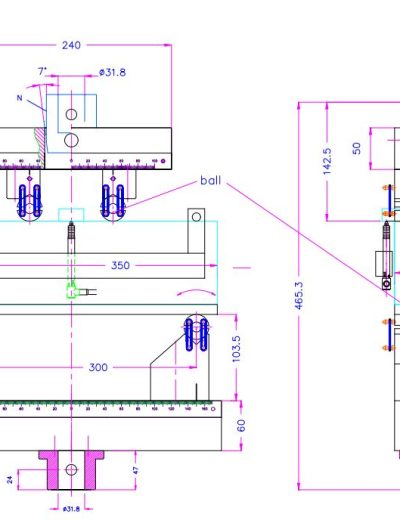

The shoulder grip with exchangeable inserts is the ideal fixture setup for testing to ASTM E8.

The fixture is designed to test button head style specimens, the same as shown in the virtualization to the left.

Flat samples are different and are usually held with wedge grips with serrated inserts.

Samples with flat shoulders may also be fixed with a clevis pin if a hole is drilled through the specimen.

Referenced Documents

ASTM Standards

ASTM A356/A356M Specification for Steel Castings, Carbon, Low Alloy, and Stainless Steel, Heavy-Walled for Steam Turbines

ASTM A370 Test Methods and Definitions for Mechanical Testing of Steel Products

ASTM B557 Test Methods for Tension Testing Wrought and Cast Aluminum- and Magnesium-Alloy Products

ASTM B557M Test Methods for Tension Testing Wrought and Cast Aluminum- and Magnesium-Alloy Products (Metric)

ASTM D1566 Terminology Relating to Rubber

ASTM E4 Practices for Force Verification of Testing Machines

ASTM E6 Terminology Relating to Methods of Mechanical Testing

ASTM E29 Practice for Using Significant Digits in Test Data to Determine Conformance with Specifications

ASTM E83 Practice for Verification and Classification of Extensometer Systems

ASTM E345 Test Methods of Tension Testing of Metallic Foil

ASTM E691 Practice for Conducting an Interlaboratory Study to Determine the Precision of a Test Method

ASTM E1012 Practice for Verification of Testing Frame and Specimen Alignment Under Tensile and Compressive Axial Force Application

ASTM E1856 Guide for Evaluating Computerized Data Acquisition Systems Used to Acquire Data from Universal Testing Machines

ASTM E2658 Practices for Verification of Speed for Material Testing Machines