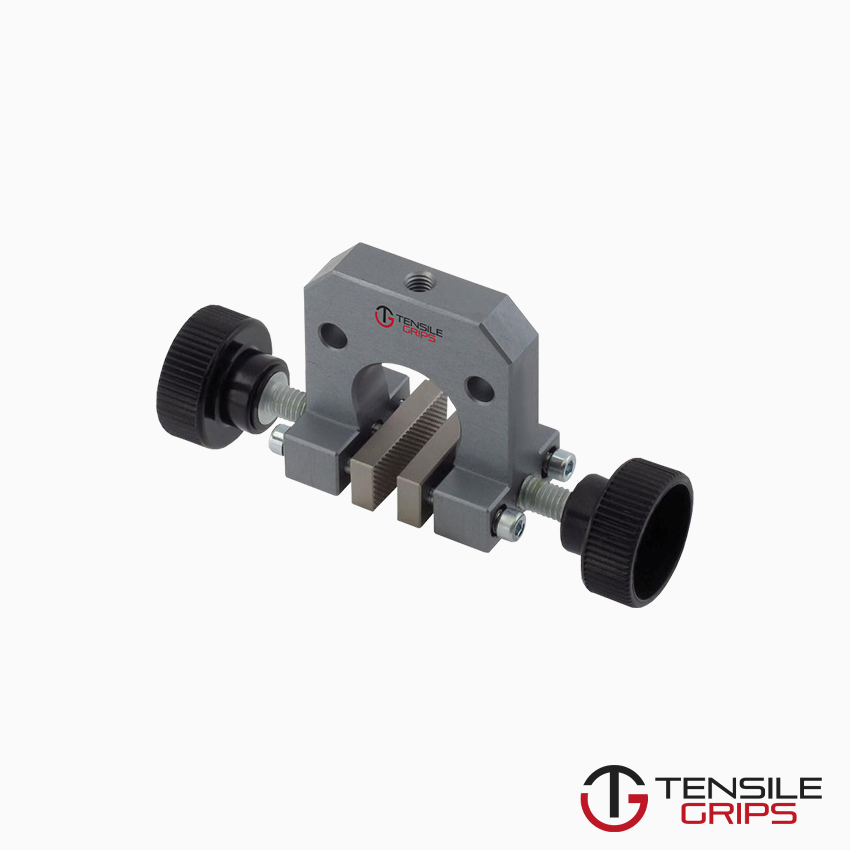

ASTM D882 Test Fixture

ASTM D882 – This test method covers the determination of tensile properties of plastics in the form of thin sheeting and films (less than 1.0 mm (0.04 in.) in thickness).

Please Contact With Us For More Information

ASTM D882 – Standard Test Method for Tensile Properties of Thin Plastic Sheeting

ASTM D882 – Thin Plastic Film Tensile Testing Fixture

ASTM D882 – This test method covers the determination of tensile properties of plastics in the form of thin sheeting and films (less than 1.0 mm (0.04 in.) in thickness).

NOTE 1: Film is defined in Terminology D883 as an optional term for sheeting having a nominal thickness no greater than 0.25 mm (0.010 in.).

NOTE 2: Tensile properties of plastics 1.0 mm (0.04 in.) or greater in thickness shall be determined according to Test Method D638.

This test method can be used to test all plastics within the thickness range described and the capacity of the machine employed.

Specimen extension can be measured by grip separation, extension indicators, or displacement of gage marks.

The procedure for determining the tensile modulus of elasticity is included at one strain rate.

ASTM D882 – Significance and Use

Tensile properties determined by this test method are of value for the identification and characterization of materials for control and specification purposes.

Tensile properties can vary with specimen thickness, method of preparation, speed of testing, type of grips used, and manner of measuring extension.

Consequently, where precise comparative results are desired, these factors must be carefully controlled.

This test method shall be used for referee purposes, unless otherwise indicated in particular material specifications.

For many materials, there can be a specification that requires the use of this test method, but with some procedural modifications that take precedence when

adhering to the specification.

Therefore, it is advisable to refer to that material specification before using this test method.

ASTM D882 – Process

ASTM D882 tests the properties of plastic films and sheeting material.

Plastic sheet is made through an extrusion process and the film is manufactured into a roll.

These rolls can then be converted and combined in a roll-to-roll manufacturiing process to create new products.

There are many properties that are critical for the success of roll-to-roll manufacturing including the tensile strength of the thin plastic film as well as

the Co-efficient of Friction.

When films are combined to form a double, triple, or multi-ply film, the unfinished product is usually referred to as the “web” because the multiple rolls that

get combined resemble a spider’s web.

Many consumer packaged goods companies (CPGs) like Kraft, Pepsi, and Procter & Gamble, perform this test.

Calculations that can be derived from this test include ultimate tensile strength, elongation, and elongation modulus.

Other advanced calculations can be made as well including the yield point and young’s modulus, however most manufacturers are only concerned with

the basic tensile testing data.

Plastic film sheet under 1mm in thickness is usually tested with rubber grip face inserts and a vise grip.

The sample specimen must break somewhere in the middle of the sample and not at the grip face, so care must be taken so that the two grips are aligned properly.

If the elongation of the sample is quite high, an extended frame must be used so that a sample break is actually achieved.

Samples for this test are generally one inch wide (25.4mm), so the standard grip face inserts of 30x30mm will be able to perform the test to the required

specifications.

*** Before conducting ASTM D882 , it is important to read the entire specification. Standards can be obtained from appropriate standard authorities.