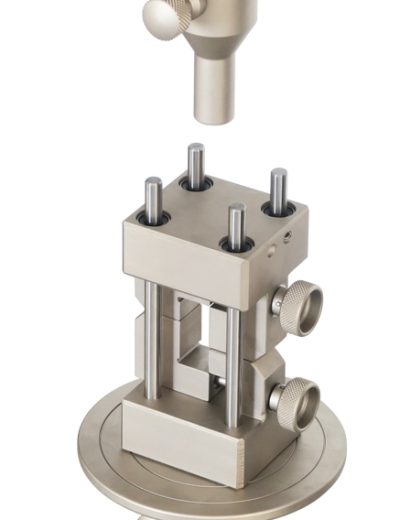

ASTM D828 Test Fixture

ASTM D828 covers procedures for determining tensile properties of paper and paperboard.

Please Contact With Us For More Information

ASTM D828 Standard Test Method for Tensile Properties of Paper and Paperboard Using Constant-Rate-of-Elongation Apparatus

ASTM D828 covers procedures for determining tensile properties of paper and paperboard.

The procedures given in this test method are for use with constant-rate-of-elongation tensile testing equipment and as such, may be used with instruments

designed for either vertical or horizontal operation, and whether manually operated or computer controlled.

These procedures are applicable for all types of paper, paperboard, paper products, and related materials within the measurement limitations of

the equipment used.

They are not for use with combined corrugated board.

Properties that may be determined using this test method include tensile strength, stretch, tensile energy absorption, tensile stiffness, breaking length,

and tensile index.

ASTM D828 – Apparatus

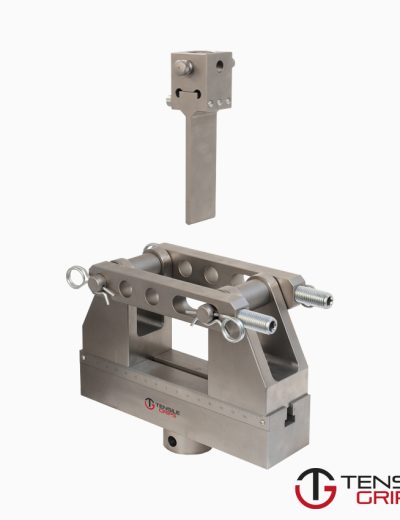

Testing Machine, of the constant-rate-of elongation type conforming to the following criteria:

Two line contact grips or jaws for gripping the test specimens, with the line of contact perpendicular to the direction of the applied load, and with means

for controlling and adjusting the clamping pressure.

NOTE 1—There are certain grades of paper that may be damaged by line contact grips.

In these cases, as agreed upon between the users of this test method, other grips may be substituted, and that fact stated in the report.

The clamping surfaces of the two grips must be in the same plane and so aligned that they hold the test specimen in that plane throughout the test.

The distance between the line contact gripping zones of the grips at the beginning of a test must be adjustable and resettable to 60.5 mm (60.02 in.)

for the specified initial test span

The rate of separation of the two grips must be 25.4 6 5.0 mm/min (1.0 6 0.2 in./min) or as otherwise noted , and once set, must be resettable and

constant at the required rate to 64 % of the specified value.

The tensile testing machine must be equipped with a load measuring device and a recorder or other suitable indicator of the measured load at points of interest

during the test, an example of which might be a micro processor and digital readout device or cathode ray tube screen, capable of reading the measured loading

force accurately to 0.25 % of the full range of the load measuring device.

The load measuring circuitry must be capable of accurate calibration, and must maintain that calibration accuracy to 60.5 % of the full-scale value.

*** Before conducting ASTM D828 , it is important to read the entire specification. Standards can be obtained from appropriate standard authorities.