ASTM D638 Test Fixture

ASTM D638 – This test method covers the determination of the tensile properties of unreinforced and reinforced plastics in the form of standard dumbbell-shaped

test specimens

Please Contact With Us For More Information

ASTM D638 – Standard Test Method for Tensile Properties of Plastics

Plastics Tensile Strength

ASTM D638 is the standard specification for plastics tensile testing.

ASTM D638 – This test method covers the determination of the tensile properties of unreinforced and reinforced plastics in the form of standard dumbbell-shaped

test specimens when tested under defined conditions of pretreatment, temperature, humidity, and testing machine speed.

This test method is applicable for testing materials of any thickness up to 14 mm (0.55 in.).

However, for testing specimens in the form of thin sheeting, including film less than 1.0 mm (0.04 in.) in thickness, ASTM standard D882 is the preferred test method.

Materials with a thickness greater than 14 mm (0.55 in.) shall be reduced by machining.

*** NOTE 1 : This standard and ISO 527-1 address the same subject matter, but differ in technical content.

*** NOTE 2 : This test method may be used for testing phenolic molded resin or laminated materials. However, where these materials are used as electrical insulation,

such materials should be tested in accordance with Test Methods D229 and Test Method D651.

*** NOTE 3 : For tensile properties of resin-matrix composites reinforced with oriented continuous or discontinuous high modulus >20-GPa (>3.0 × 106-psi) fibers,

tests shall be made in accordance with Test Method D3039/D3039M.

ASTM D638 – Geometry

This test uses a standard “dogbone” style sample.

There are a few different types of geometries, however the cross-sectional area is the only important factor.

Generally dogbones that are less than 14mm thick are tested. Please see the official specification for more information on the size and shape of the samples.

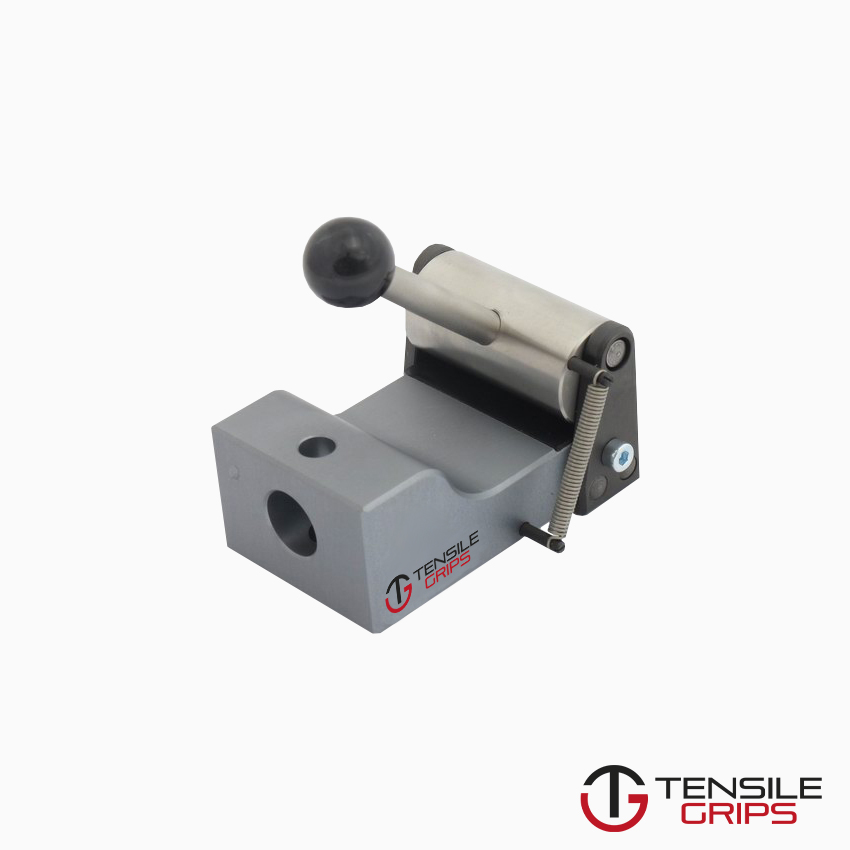

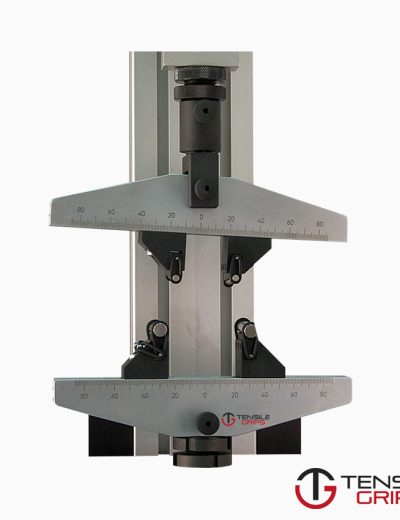

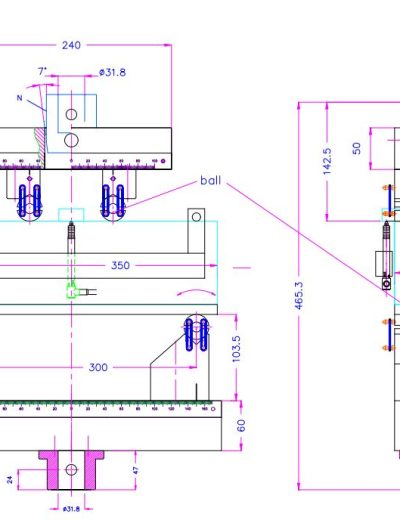

ASTM D638 – Solution

There are several types of grips that can work for this application and selecting the right one largely depends on the exact material and sample geometry.

TG recommends the roller grips for tests below about 500 lbs.

The hook attachment adds a nice self-centering feature which is also cost effective.

Vise Grips can also be used but wedge grips are necessary for higher strength samples.

Serrated grip jaws are able to bite into the sample and secure it properly.

Referenced Documents

ASTM Standards

D229 Test Methods for Rigid Sheet and Plate Materials Used for Electrical Insulation

D412 Test Methods for Vulcanized Rubber and Thermoplastic Elastomers–Tension

D618 Practice for Conditioning Plastics for Testing

D651 Test Method for Test for Tensile Strength of Molded Electrical Insulating Materials

D882 Test Method for Tensile Properties of Thin Plastic Sheeting

D883 Terminology Relating to Plastics

D1822 Test Method for Tensile-Impact Energy to Break Plastics and Electrical Insulating Materials

D3039/D3039M Test Method for Tensile Properties of Polymer Matrix Composite Materials

D4000 Classification System for Specifying Plastic Materials

D4066 Classification System for Nylon Injection and Extrusion Materials (PA)

D5947 Test Methods for Physical Dimensions of Solid Plastics Specimens

E4 Practices for Force Verification of Testing Machines

E83 Practice for Verification and Classification of Extensometer Systems

E132 Test Method for Poissons Ratio at Room Temperature

E691 Practice for Conducting an Interlaboratory Study to Determine the Precision of a Test Method

E1012 Practice for Verification of Testing Frame and Specimen Alignment Under Tensile and Compressive Axial Force Application

ISO Standard

ISO 527-1 Determination of Tensile Properties

ISO 527–1 Determination of Tensile Properties