ASTM D571 Test Fixture

ASTM D571 covers, but are not limited to, rubber-coated fabrics, that is, tarpaulins, rainwear, and similar products.

Please Contact With Us For More Information

ASTM D571 Standard Test Methods for Coated Fabrics

ASTM D571 covers, but are not limited to, rubber-coated fabrics, that is, tarpaulins, rainwear, and similar products.

Significance and Use

Coated fabrics and rubber products made from coated fabrics are important items of commerce, and adequate test methods must be available to ensure

the quality of these products.

These test methods provide for this testing capability

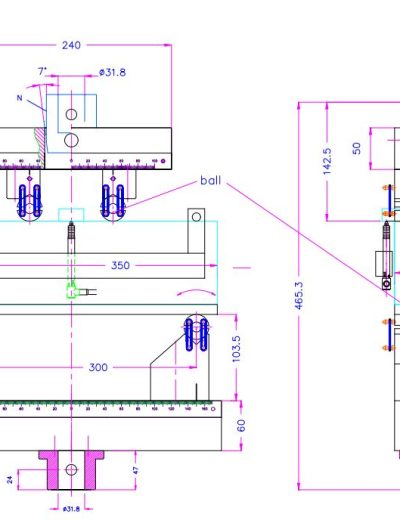

ASTM D751 / Testing Machine

The machine shall consist of three main parts:

Straining mechanism,

Clamps for holding specimen, and

Load and elongation recording mechanism(s).

ASTM D571 / Straining Mechanism

A machine wherein the specimen is held between the two clamps and strained by a uniform movement of the pulling clamp shall be used.

Unless otherwise specified in the material specification, the machine shall be adjusted so that the pulling clamp shall have a uniform speed of

5 6 0.2 mm/s (12 6 0.5 in./min).

ASTM D571 / Load and Elongation Recording Mechanism(s)

Calibrated dial, scale, or chart to indicate applied load and elongation.

Unless otherwise specified for load determination, the machine shall be adjusted or set so that the maximum load required to break the specimen will

remain indicated on the calibrated dial, scale, chart, autographic recording, or computer interfaced with the testing machine after the test specimen has ruptured.

ASTM D571 / Capacity

The machine shall be of such capacity that the maximum load required to break the specimen shall be not greater than 85 % or less than 15 % of the rated capacity.

Machine Effıciency—The error of the machine shall not exceed 2 % up to and including a 222-N (50-lbf) force and 1 % over 222 N and 1 % at any reading within its loading range.

ASTM D751 / Clamps for Fabrics

The clamps for holding a specimen of coated fabric shall have gripping surfaces sufficiently flat and parallel as to prevent the test specimen from slipping

or moving between the gripping surfaces when held under the pressure normal to operation.

The dimension of all gripping surfaces parallel to the direction of application of the load shall be 25 mm (1 in.); the dimension perpendicular to this direction shall be

1 in. for the face jaw and 50 mm (2 in.) or more for the other.

All edges that might cause a cutting action shall be rounded to a radius of not over 0.4 mm (0.0156 in.).

The pressure between the gripping surfaces, sufficient to clamp the specimen firmly before the testing load is applied and to prevent slippage during the progress

of the test, shall be secured by any suitably constructed mechanical device operating on the member of the clamp.

The distance between the clamps at the start of the test shall be 75 mm (3 in.)

*** Before conducting ASTM D751 , it is important to read the entire specification. Standards can be obtained from appropriate standard authorities.