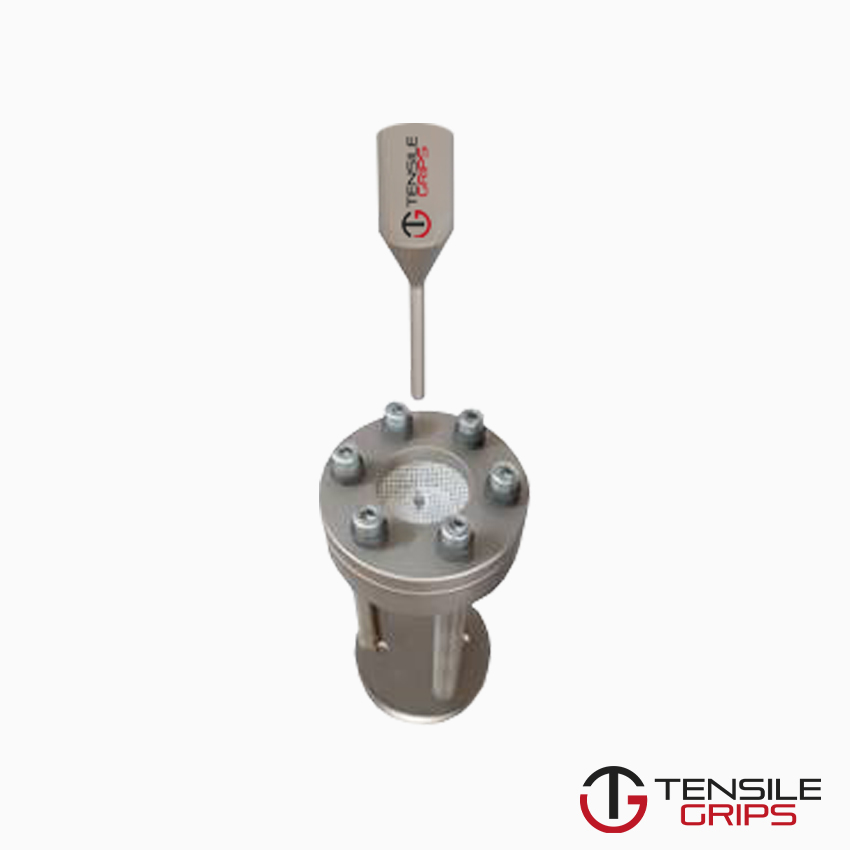

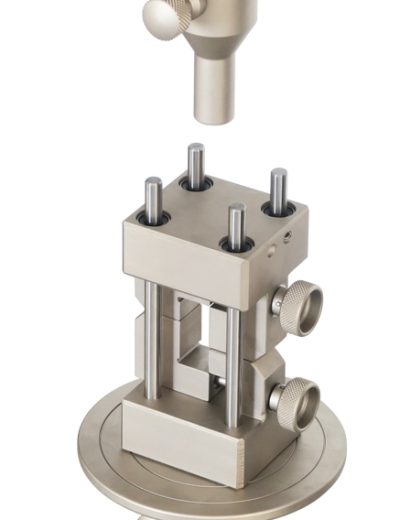

ASTM D4833 Test Fixture

ASTM D4833 – This test method is used to measure the index puncture resistance of geomembranes and related products.

Please Contact With Us For More Information

ASTM D4833 – Standard Test Method for Index Puncture Resistance of Geomembranes and Related Products

Geomembrane Puncture Fixture

ASTM D4833 – This test method is used to measure the index puncture resistance of geomembranes and related products.

The use of Test Method D 4833 may be inappropriate for testing some woven geotextiles or related products which have large openings, such as

geonets and geogrids.

It is recommended that geotextile and geotextile related products be tested using Test Method D 6241

ASTM D4833 –Significance and Use

This test method is an index test for determining the puncture resistance of geomembranes and related products.

The use of this test method is to establish an index value by providing standard criteria and a basis for uniform reporting.

This test method is considered satisfactory for acceptance testing of commercial shipments of geomembranes and related materials

since the test method has been used extensively in the trade for acceptance testing.

In case of a dispute arising from differences in reported test results when using this test method for acceptance testing of commercial shipments,

the purchaser and the supplier should conduct comparative tests to determine if there is a statistical bias between their laboratories.

Competent statistical assistance is recommended for the investigation of bias.

As a minimum, the two parties should take a group of test specimens that are as homogeneous as possible and that are from a lot material of the type in question.

The test specimens should then be randomly assigned in equal numbers to each laboratory for testing.

The average results from the two laboratories should be compared using Student’s t-test for unpaired data and an acceptable probability level chosen by the

two parties before the testing is begun.

If a bias is found, either its cause must be found and corrected or the purchaser and the supplier must agree to interpret future test results in the light of the

known bias.

ASTM D4833 –Geometry

There are two key elements to this procedure. The first is the geometry of the puncture implement which is 8mm in diamater with a 45 degree beveled or

chamfered edge.

The second is the size of the open hole in the clamping jig.

ASTM D4833 –Solution

The clamping jig and puncture implement are available as a package.

They use a standard 1.25 inch or 5/8″ adapter to attach to the top and bottom of the testing machine.

It is vitally important that the user pre-specifies enough capacity so that the test actually achieves full puncture and the proper calculations can be made.

Analysis

There are several calculations that are common across most puncture tests.

They include the average puncture stength which is an average of the peak load across multiple specimens of the same type of sample.

An average must be taken because textiles are non uniform based on their woven stricture. Other calculations are centered around the variability and deviation

between tests.