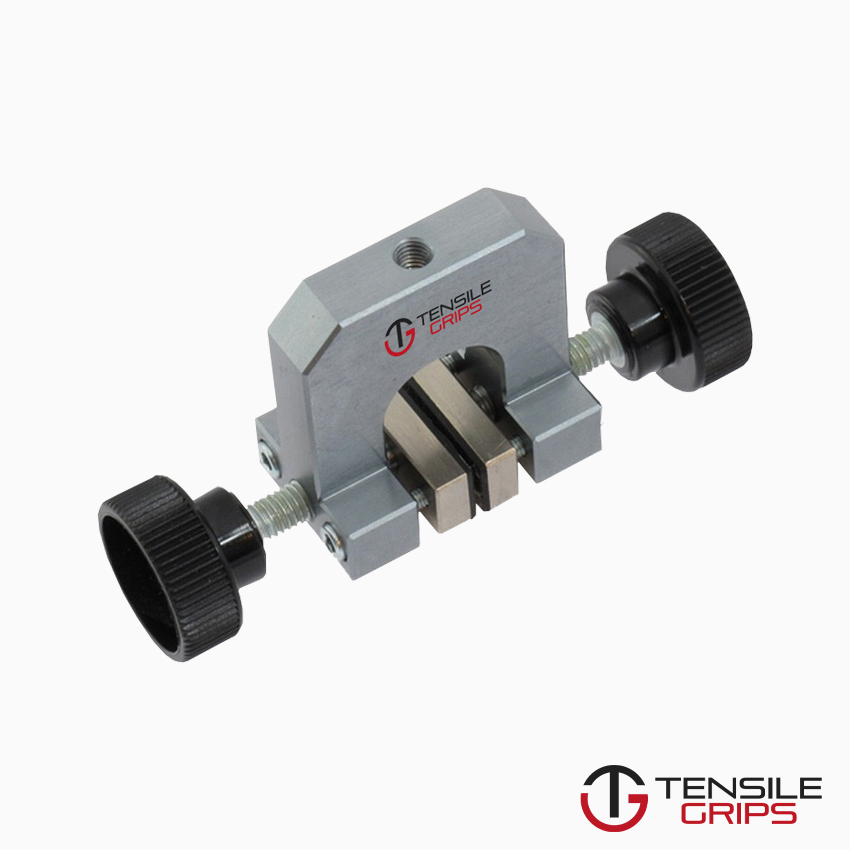

ASTM D413 Test Fixture

ASTM D413 – This test method covers the determination of the adhesion strength between plies of fabric bonded with rubber or the adhesion of the

rubber layer in articles made from rubber attached to other material.

Please Contact With Us For More Information

ASTM D413 – Standard Test Methods for Rubber Property—Adhesion to Flexible Substrate

ASTM D413 – This test method covers the determination of the adhesion strength between plies of fabric bonded with rubber or the adhesion of the

rubber layer in articles made from rubber attached to other material.

They are applicable only when the adhered surfaces are approximately plane or uniformly circular as in belting, hose, tire carcasses, or rubber-covered sheet

metal.

When the adhered surfaces contain sharp bends, angles, or other gross irregularities that cannot be avoided in preparing test specimens, special test methods

must be employed for evaluating adhesion.

This test method is used to ensure the quality of a product by determining the force per unit width required to separate a rubber layer from a flexible substrate such

as fabric, fibre, wire, or sheet metal.

The acceptable value of adhesion measured will, of course, vary from product to product due to different rubber formulations, flexible substrates, and types of products.

However, once a product is established, minimum values of separation force can be determined and agreed to by producer and consumer and both can monitor

to assure maintenance of the agreed-upon minimum value.

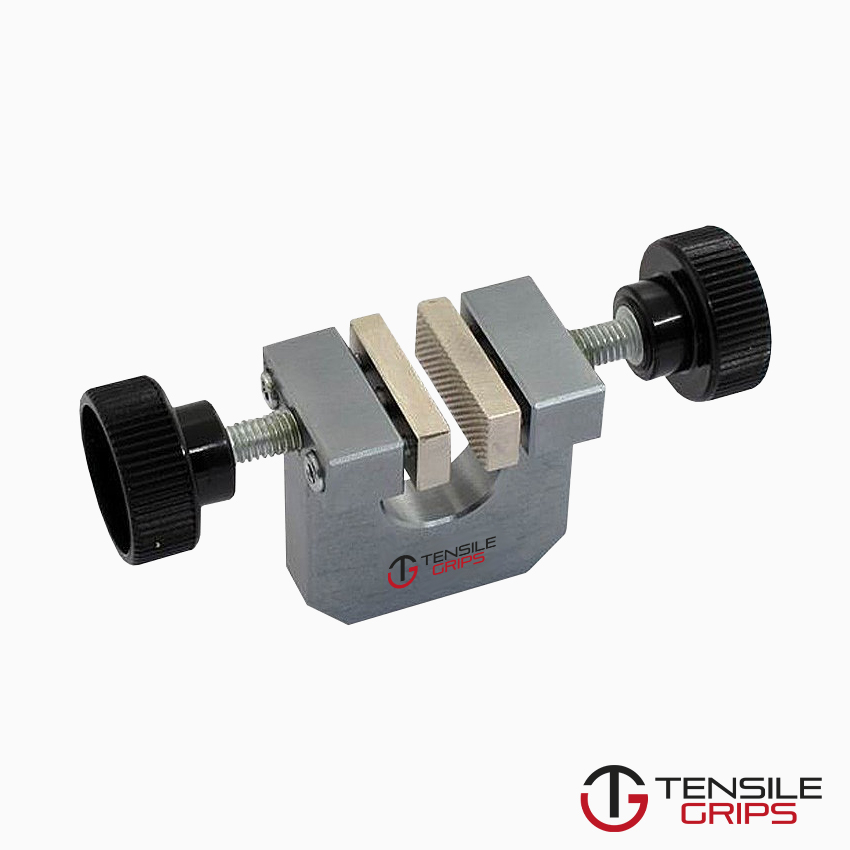

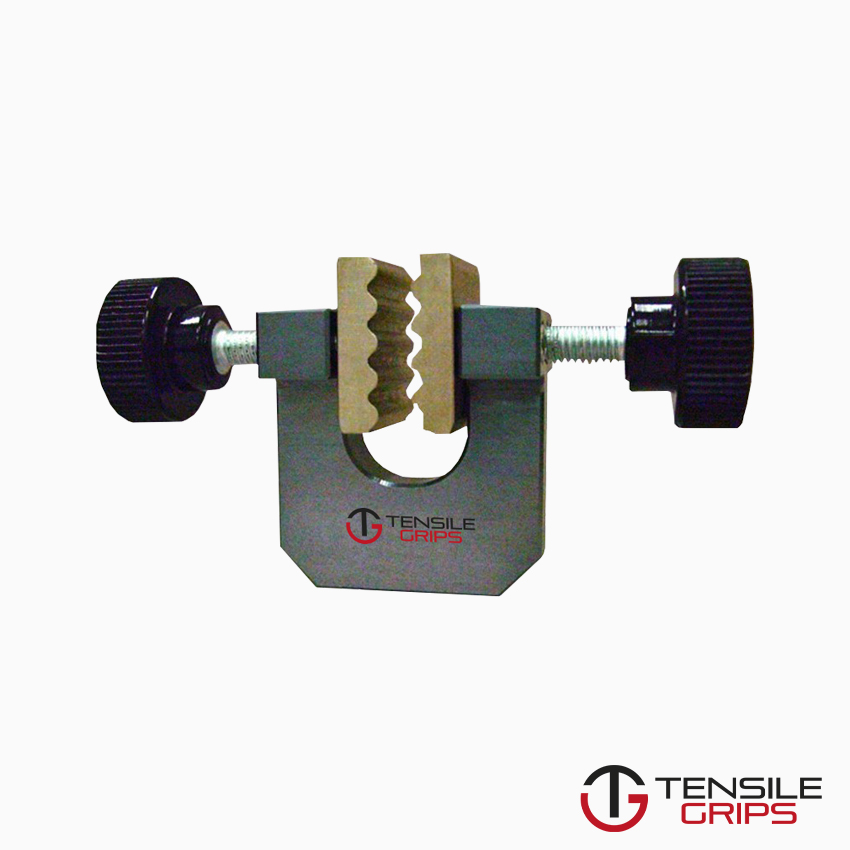

ASTM D413 – Method A – 180 Degree Peel

For Type A, you must perform a 180 degree peel. Separate the parts to be tested by hand at one end of the test specimen and at a sufficient distance to permit grips

of the machine to be attached.

Attach the separated end of the specimen, with all separate parts except the one under test securely gripped, to the recording head by means of a grip.

Provide for maintaining the strip during the test approximately in the plane of the clamps.

Grip that layer of the specimen of which the adhesion is to be tested symmetrically and firmly without twisting in the power-actuated clamp.

Start the machine.

Strip the separating layer from the specimen at an angle of approximately 180 degree, and continue the separation for a sufficient distance to indicate

the adhesion value.

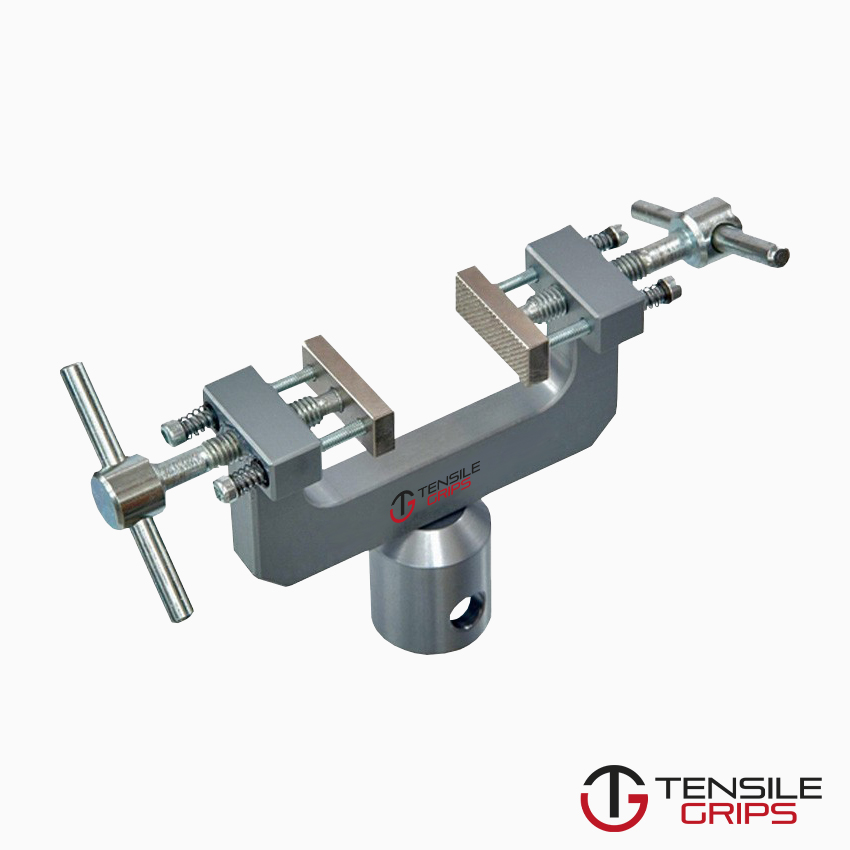

ASTM D413 – Method B – 90 Degree Peel

Type B requires a 90 degree peel.

Separate by hand a sufficient distance along the separation line in the center of the strip to permit the grips of the machine to be attached.

Peel along the previously cut separation layer for 40 to 100 mm.

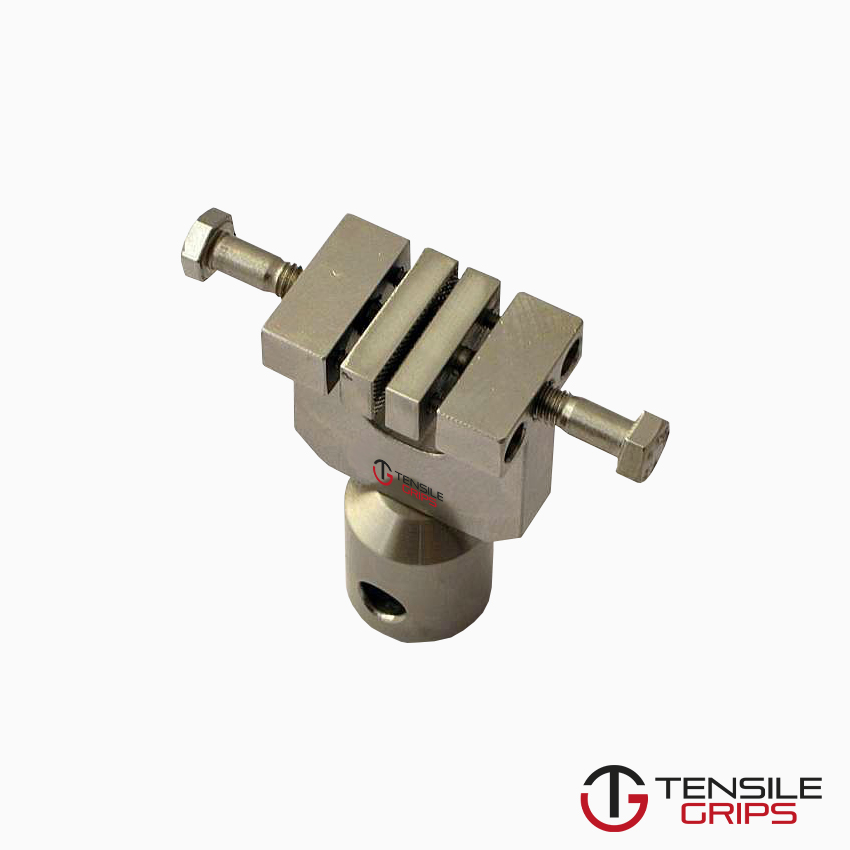

ASTM D413 / Method C – 90 Degree Peel

Type C is for ring specimens.

Separate by hand a sufficient length of a layer of the specimen to be tested to permit the power actuated clamp of the machine to be attached.

Place the specimen snugly on the test mandrel.

With the mandrel attached to the recording head of the machine and the separated layer gripped symmetrically and firmly without twisting in the power-actuated

clamp, and start the machine.

Strip the separating layer from the specimen at an angle of approximately 90 degree to the tangent of the specimen surface, and continue the separation

for a sufficient distance to indicate the adhesion value.

During the test, the mandrel shall rotate freely so as to maintain the line of separation at all times approximately in the same position.

**** Test Types A, B & C of ASTM D413 require a peel test machine that can perform both 180 and 90 degree peels

Referenced Documents

ASTM Standards

ASTM D3040 Practice for Preparing Precision Statements for Standards Related to Rubber and Rubber Testing

ASTM D3182 Practice for RubberMaterials, Equipment, and Procedures for Mixing Standard Compounds and Preparing Standard Vulcanized Sheets

ASTM D3183 Practice for RubberPreparation of Pieces for Test Purposes from Products