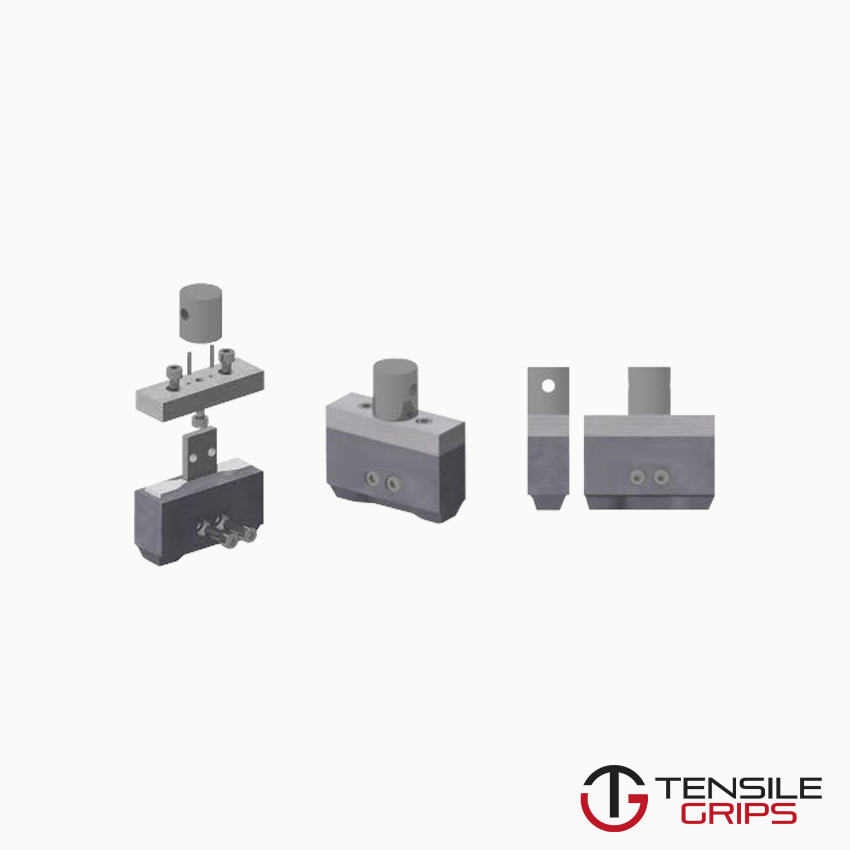

ASTM D412 Test Fixture

ASTM D412 – This test method covers procedures used to evaluate the tensile (tension) properties of vulcanized thermoset rubbers and thermoplastic elastomers.

Please Contact With Us For More Information

ASTM D412 – Standard Test Methods for Vulcanized Rubber and Thermoplastic Elastomers—Tension

ASTM D412 Rubber Tensile Test Fixture

ASTM D412 – This test method covers procedures used to evaluate the tensile (tension) properties of vulcanized thermoset rubbers and thermoplastic elastomers.

These methods are not applicable to ebonite and similar hard, low elongation materials.

The methods appear as follows:

| Test Method A—Dumbbell and Straight Section Specimens |

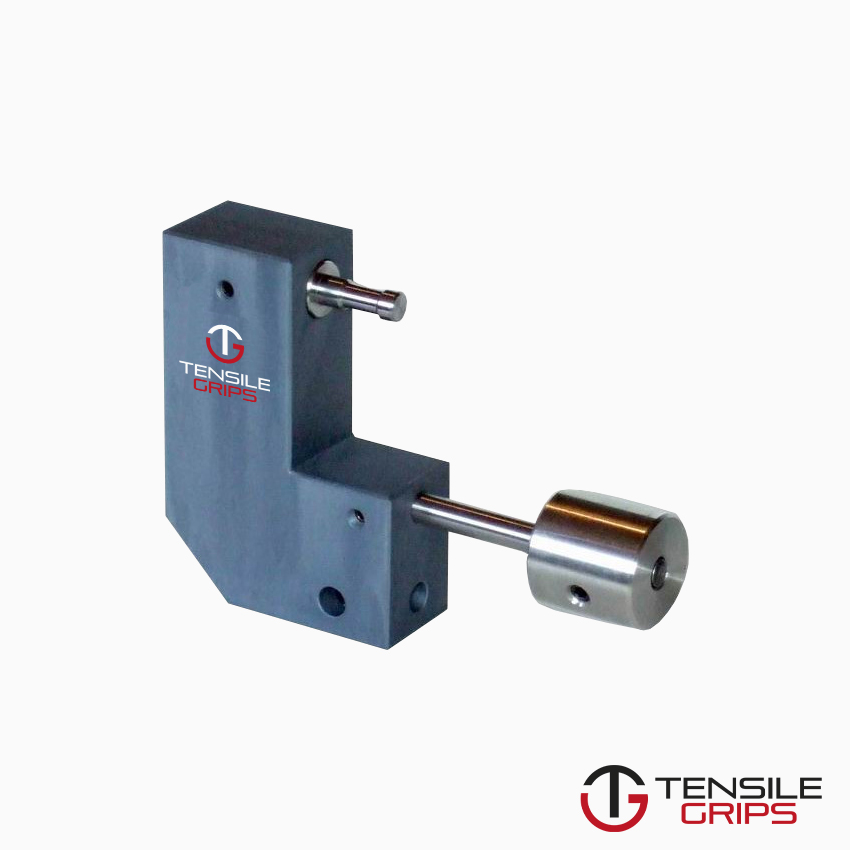

| Test Method B—Cut Ring Specimens |

NOTE 1: These two different methods do not produce identical results.

ASTM D412 – Significance and Use

All materials and products covered by these test methods must withstand tensile forces for adequate performance in certain applications.

These test methods allow for the measurement of such tensile properties.

However, tensile properties alone may not directly relate to the total end use performance of the product because of the wide range of potential performance

requirements in actual use.

Tensile properties depend both on the material and the conditions of test (extension rate, temperature, humidity, specimen geometry, pretest conditioning, etc.);

therefore materials should be compared only when tested under the same conditions.

Temperature and rate of extension may have substantial effects on tensile properties and therefore should be controlled.

These effects will vary depending on the type of material being tested.

Tensile set represents residual deformation which is partly permanent and partly recoverable after stretching and retraction.

For this reason, the periods of extension and recovery (and other conditions of test) must be controlled to obtain comparable results.

ASTM D412 – Geometry

Specimens for this procedure are usually of the “dogbone” variety or lesser referred to as the “barbell” shape.

The exact required geometry for these samples can be found in the appropriate ASTM publication, or with a bit of hunting around on the Google machine.

As with most material testing applications, the geometry of the cross-sectional area is the main focus.

Rubbers can stretch to 3 or 4 times their original length which means that consideration must be made towards the total crosshead travel (stroke) of the

tensile tester.

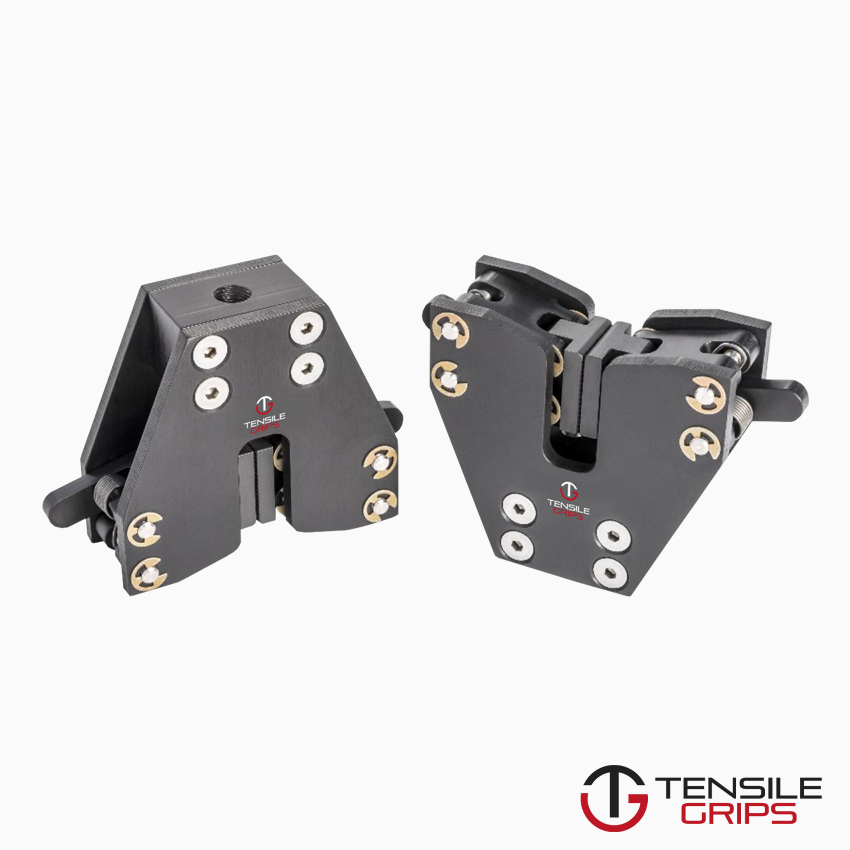

ASTM D412 – Solution

There are several grips and fixtures which can test elastomeric polymers.

These materials tend to thin out during the test due to their weak intermolecular bonds, so self tightening grips work best.

These include those of the roller variety, as well as the scissor grips.

Pneumatic grips also work well but are more expensive and less foolproof.

Referenced Documents

ASTM Standards

ASTM D1349 Practice for RubberStandard Conditions for Testing

ASTM D1566 Terminology Relating to Rubber

ASTM D3182 Practice for RubberMaterials, Equipment, and Procedures for Mixing Standard Compounds and Preparing Standard Vulcanized Sheets

ASTM D3183 Practice for RubberPreparation of Pieces for Test Purposes from Products

ASTM D3767 Practice for RubberMeasurement of Dimensions

ASTM D4483 Practice for Evaluating Precision for Test Method Standards in the Rubber and Carbon Black Manufacturing Industries

ASTM E4 Practices for Force Verification of Testing Machines

ISO Standards

ISO 37