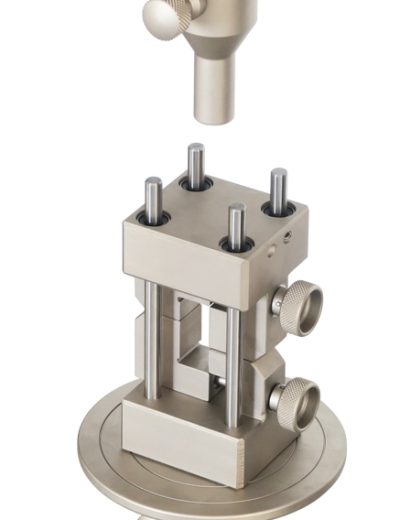

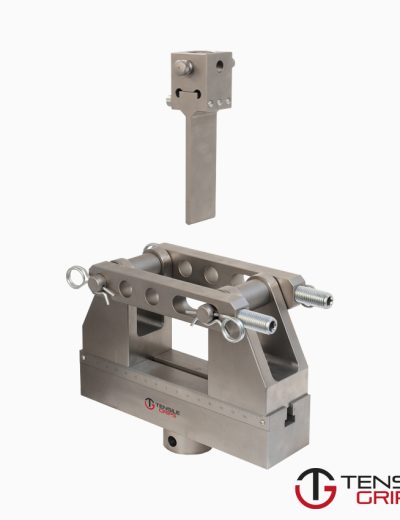

ASTM D3433 Test Fixture

ASTM D3433 – This test method (1, 2, 3, 4, 5)2 covers the determination of fracture strength in cleavage of adhesives when tested on standard specimens

and under specified conditions of preparation and testing

Please Contact With Us For More Information

Category:

ASTMTags:

ADHESION TENSILE TESTS, ADHESIVE FRACTURE TESTS, ADHESIVE TENSILE TEST MACHINES, ADHESIVE TEST FIXTURES, ASTM D3433, CRACK GROWTH AND PROPAGATION, CRACK GROWTH OF ADHESIVES, ELECTROMECHANIC TENSILE MACHINES, FRACTURE CLEAVAGE ADHESIVES TESTING MACHINE, FRACTURE TEST OF ADHESIVES, METAL BONDING ADHESIVES, SERVO HYDRAULIC TENSILE TEST MACHINESASTM D3433 – Standard Test Method for Fracture Strength in Cleavage of Adhesives in Bonded Metal Joints

ASTM D3433 – Fracture Cleavage Adhesives Testing Machine & Fixtures

ASTM D3433 – This test method (1, 2, 3, 4, 5)2 covers the determination of fracture strength in cleavage of adhesives when tested on standard specimens

and under specified conditions of preparation and testing

This test method is useful in that it can be used to develop design parameters for bonded assemblies.

NOTE 1: While this test method is intended for use in metal-to-metal applications it may be used for measuring fracture properties of adhesives using plastic

adherends, provided consideration is given to the thickness and rigidity of the plastic adherends.

Significance and Use

This test method can serve the following purposes:

In research and development to establish, in quantitative terms, significant to service performance, the effects of adhesive composition, primers, adherend surface

treatments, supporting adhesive carriers (scrim), processing variables, and environmental effects.

In service evaluation to establish the suitability of an adhesive system for a specific application for which the stress conditions are prescribed and for which

maximum flaw sizes can be established with confidence.

For specifications of acceptance and manufacturing quality control, but only when there is a sound basis for specification of minimum G1c values.

The specification of G1c valuesin relation to a particular application should signify that a fracture control study has been conducted on the component in relation

to the expected history of loading and environment,and in relation to the sensitivity and reliability of the crack detection procedures that are to be applied prior to

service and subsequently during the anticipated life.

*** Before conducting ASTM D3433 , it is important to read the entire specification. Standards can be obtained from appropriate standard authorities.