ASTM D1002 Test Fixture

ASTM D1002 – This Standard determines the shear strength of adhesives for bonding metals when tested on a single-lap-joint specimen.

Please Contact With Us For More Information

ASTM D1002 – Standard Test Method for Apparent Shear Strength of Single-Lap-Joint Adhesively Bonded Metal Specimens by Tension Loading (Metal-to-Metal)

ASTM D1002 – This Standard determines the shear strength of adhesives for bonding metals when tested on a single-lap-joint specimen.

The test is applicable for determining adhesive strength, surface preparation parameters, and adhesive environmental durability.

There are over 20 more ASTM specific tests for testing the shear strength of an adhesively bonded material.

This outline focuses on metal to metal bonds. Several types of laps exist including bevelled, double, double butt, joggle, and single.

There are several failure modes for the lap shear test.

The adhesive can detach from the metal substrate, the adhesive can seperate from itself, or the adhesive could be so strong that it actually shears

the metal and tears a chunk of it away.

There are a variety of ASTM single-lap-joint shear tests including ASTM D1002 which specifies lap shear for metal to metal, ASTM D3163 for plastics joints, and

ASTM D5868 for fiber reinforced plastics (FRP) against itself or metal.

ASTM D1002 – Test Procedure

Two metal plates are bonded together with adhesive and cured as specified. The assembly is then cut into uniform width lap shear specimens.

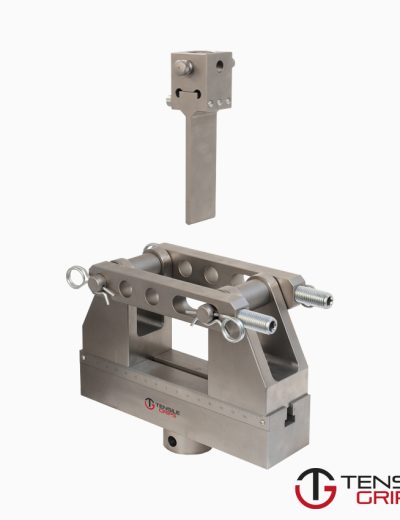

The test specimens are placed in the grips of a universal testing machine and pulled at 1.3 mm/min (0.05 in/min) until rupture occurs.

The grips used to secure the ends of the assembly must align so that the applied force is applied through the centerline of the specimen.

The type of failure can be either adhesive (the adhesive separates from one of the substrates) or cohesive (the adhesive ruptures within itself).

ASTM D1002 – Specimen Geometry

The recommended lap shear specimen is 25.4 mm (1”) wide, with an overlap of 12.7 mm (0.5”).

The recommended metal thickness is 1.62 mm (0.064”) and the overall length of the bonded specimen should be 177.8 mm (7”).

The specimen failure should occur in the adhesive, and not in the substrate – thus the metal thickness and the length of the overlap may be adjusted as necessary.

Adhesive is applied based on manufacturer recommendations.

Equipments for the test

*Universal Testing Machine

*Hand Tightened Grips that allow for proper alignment

*Air recirculation oven for curing of adhesives

The values reported for the lap shear test are relatively straight forward.

The maximum force, also commonly referred to as the shear strength, is really just the peak load.

The maximum shear stress is slightly different and requires the user to divide the maximum force by the area.

The units are then reported as PSI or similar. The failure mode should also be recorded.

ASTM D1002 – Testing Fixtures – Apparatus

Wedge Grips are the defacto selection because of the high amount of force that is usually required to successfuly

perform this procedure.

Other solutions such as hydraulic grips are also acceptable.

Referenced Documents

ASTM Standards

A109/A109M Specification for Steel, Strip, Carbon (0.25 Maximum Percent), Cold-Rolled

A167 Specification for Stainless and Heat-Resisting Chromium-Nickel Steel Plate, Sheet, and Strip

B36/B36M Specification for Brass Plate, Sheet, Strip, And Rolled Bar

B152/B152M Specification for Copper Sheet, Strip, Plate, and Rolled Bar

B209 Specification for Aluminum and Aluminum-Alloy Sheet and Plate

B265 Specification for Titanium and Titanium Alloy Strip, Sheet, and Plate

D907 Terminology of Adhesives

D4896 Guide for Use of Adhesive-Bonded Single Lap-Joint Specimen Test Results

E4 Practices for Force Verification of Testing Machines

E177 Practice for Use of the Terms Precision and Bias in ASTM Test Methods

E691 Practice for Conducting an Interlaboratory Study to Determine the Precision of a Test Method