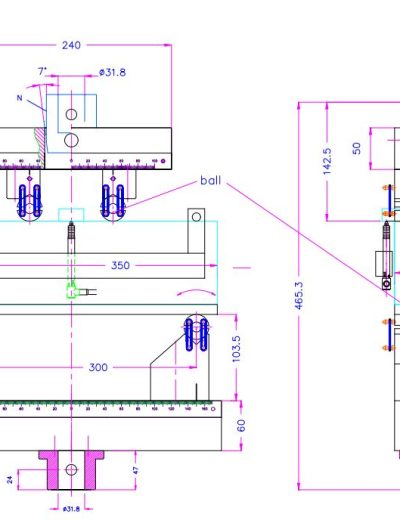

ASTM D1000 Test Fixture

ASTM D1000 – This test method covers several test methods for the characterization of tapes used in electrical applications.

Please Contact With Us For More Information

ASTM D1000 – Standard Test Methods for Pressure-Sensitive Adhesive-Coated Tapes Used for Electrical and Electronic Applications

ASTM D1000 – This test method covers several test methods for the characterization of tapes used in electrical applications.

These test methods cover procedures for testing pressure-sensitive adhesive-coated tapes to be used as electrical insulation.

*** These tapes are classified as follows:

Class 1—Non-elastomeric backings made from materials such as

Paper, flat or creped,

Fabric, uncoated or coated,

Cellulose ester films,

Polyethylene terephthalate (polyester) films,

Fluorocarbon polymer films,

Composite filament films,

Polyamide films,

Polyimide films, and

Combinations thereof.

Class 2—Elastomeric backings that are characterized by both high stretch and substantial recovery.

These backings are made from materials such as ;

Vinyl chloride and co-polymers,

Vinylidene chloride and co-polymers, and

Polyethylene and co-polymers.

ASTM D1000 / Unwind Force

Pressure Sensitive Adhesive tapes are sold in rolls. In automated manufacturing environments, these rolls are loaded into a machine for assembly.

The unwind force is an important specification because it may affect the machine behavior.

Unwind force also plays a role in logistics environments where packages are being wrapped, taped and shipped off to their destination.

ASTM D1000 / Geometry

The unwind force at the specified rate gives information on the combined effects of the interlayer adhesion in the roll and of the physical condition of the backing

and adhesive mass.

This unwind force is useful as a measure of the effects of natural, shelf or accelerated aging, and the unwind force determined at the fast rate of removal is useful

as a measure of the ease of unwinding in mechanized or hand dispensers.

A tape width of 25 mm (1 in.) is considered optimum for this test method.

The unwind force for widths other than 25 mm (1 in.) is not always proportional to the width.

ASTM D1000 / Solution

A motorized system must be used to unwind the tape, as demonstrated in the video.

The speed of the unwind must be 150 ft/min.

The top grip holds the roll of tape so that it can unwind freely and then spool onto the new roll which is attached to the motorized fixture.

Referenced Documents

ASTM Standards

A666 Specification for Annealed or Cold-Worked Austenitic Stainless Steel Sheet, Strip, Plate, and Flat Bar

D149 Test Method for Dielectric Breakdown Voltage and Dielectric Strength of Solid Electrical Insulating Materials at Commercial Power Frequencies

D257 Test Methods for DC Resistance or Conductance of Insulating Materials

D295 Test Methods for Varnished Cotton Fabrics Used for Electrical Insulation

D374/D374M Test Methods for Thickness of Solid Electrical Insulation

D1711 Terminology Relating to Electrical Insulation

D3487 Specification for Mineral Insulating Oil Used in Electrical Apparatus

D5032 Practice for Maintaining Constant Relative Humidity by Means of Aqueous Glycerin Solutions

E691 Practice for Conducting an Interlaboratory Study to Determine the Precision of a Test Method

IEC Standard

IEC60454-3 Specification for Pressure-Sensitive Adhesive Tapes for Electrical Purposes International

Electrotechnical Commission, 446 Main St., Worcester, MA 01608

ICS Code

ICS Number Code 29.035.20 (Plastic and rubber insulating materials)

UNSPSC Code

UNSPSC Code 31201502(Electrical insulating tape)