ASTM C719 Test Fixture

ASTM C719 is an accelerated laboratory procedure for evaluating the performance of a building sealant in a test configuration that is subjected to water immersion,

cyclic movement, and temperature change

Please Contact With Us For More Information

ASTM C719 Standard Test Method for Adhesion and Cohesion of Elastomeric Joint Sealants

Under Cyclic Movement (Hockman Cycle)

ASTM C719 is an accelerated laboratory procedure for evaluating the performance of a building sealant in a test configuration that is subjected to water immersion,

cyclic movement, and temperature change

Significance and Use

The failure of a building sealant in an active joint is usually manifested by cohesive failure in the sealant or adhesive failure between the sealant and the substrate, or both.

The method described in this test method relates only to the performance of the sealant when properly installed with recommended primers, and does not evaluate

sealant failures caused by improper joint design, excessive joint movement, improper application practices, and other factors known to cause sealant failure in

buildings and building areas.

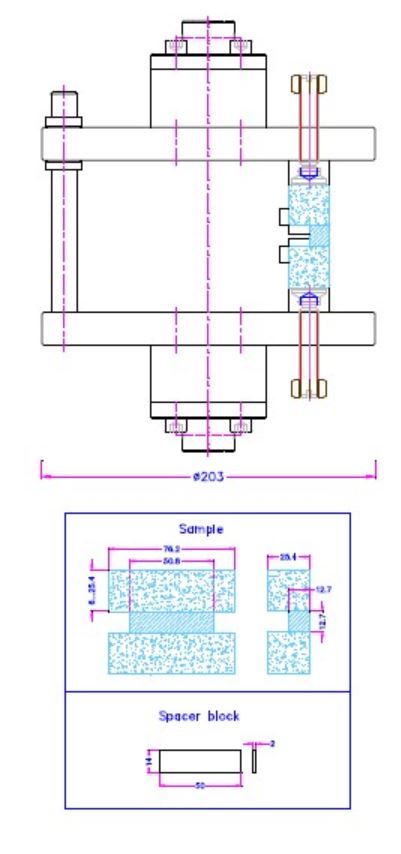

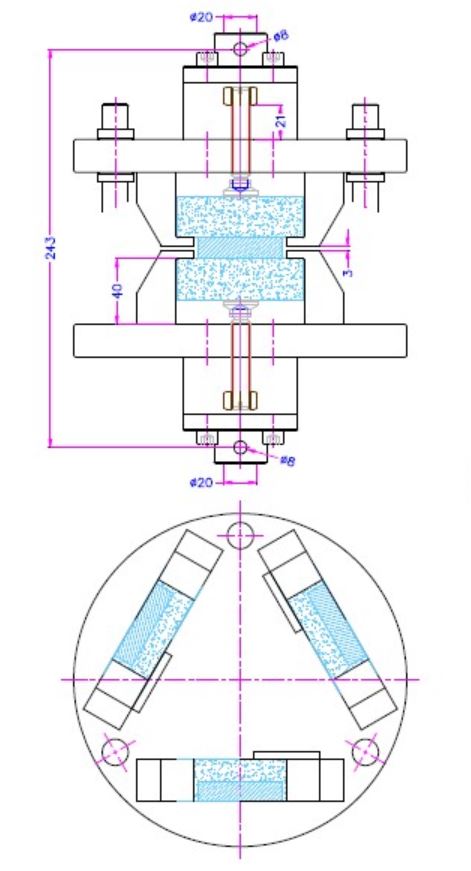

Apparatus

Compression-Extension Machine, designed to automatically compress the joint width of the test specimen from 1⁄2 in. (12.7 mm) to the minimum dimension

desired and extend the specimen from 1⁄2 in. to the maximum extension at a constant rate of 1⁄8 in./h (3.2 mm/h).

The machine shall be equipped with grips of sufficient strength to withstand, without bending, the resistance of high tensile strength sealants

Cold Box or Chamber, maintained at − 15 6 3°F (−26.1 6 1.7°C).

Forced-Draft Oven, controlled at 158 6 3.6°F (70 6 2°C).

C-clamps, or other device for maintaining the specimen under compression.

Spacer Blocks.

Room or Chamber, maintained at standard conditions of 73.4 6 3.6°F (23 6 2°C), 50 6 5 % relative humidity.

*** Before conducting ASTM C719 , it is important to read the entire specification. Standards can be obtained from appropriate standard authorities.