ASTM C273 Test Fixture

Standard Test Method for Shear Properties of Sandwich Core Materials

ASTM C273 covers the determination of shear properties of sandwich construction core materials associated with shear distortion of planes parallel to the facings.

Please Contact With Us For More Information

ASTM C273 – Standard Test Method for Shear Properties of Sandwich Core Materials

Standard Test Method for Shear Properties of Sandwich Core Materials

ASTM C273 covers the determination of shear properties of sandwich construction core materials associated with shear distortion of planes parallel to the facings.

It covers the determination of shear strength parallel to the plane of the sandwich, and the shear modulus associated with strains in a plane normal to the facings.

The test may be conducted on core materials bonded directly to the loading plates or the sandwich facings bonded to the plates.

ASTM C273 is used to determine the shear properties of construction materials that have a sandwich core.

An example of a sandwich panel, (two sandwich facings and one core), would be rigid foam insulation that is sandwiched in between two pieces of plywood.

The test is a compression based load deflection test but can also be used in the tensile mode if the sandwich facings are glued to the support plates of the fixture.

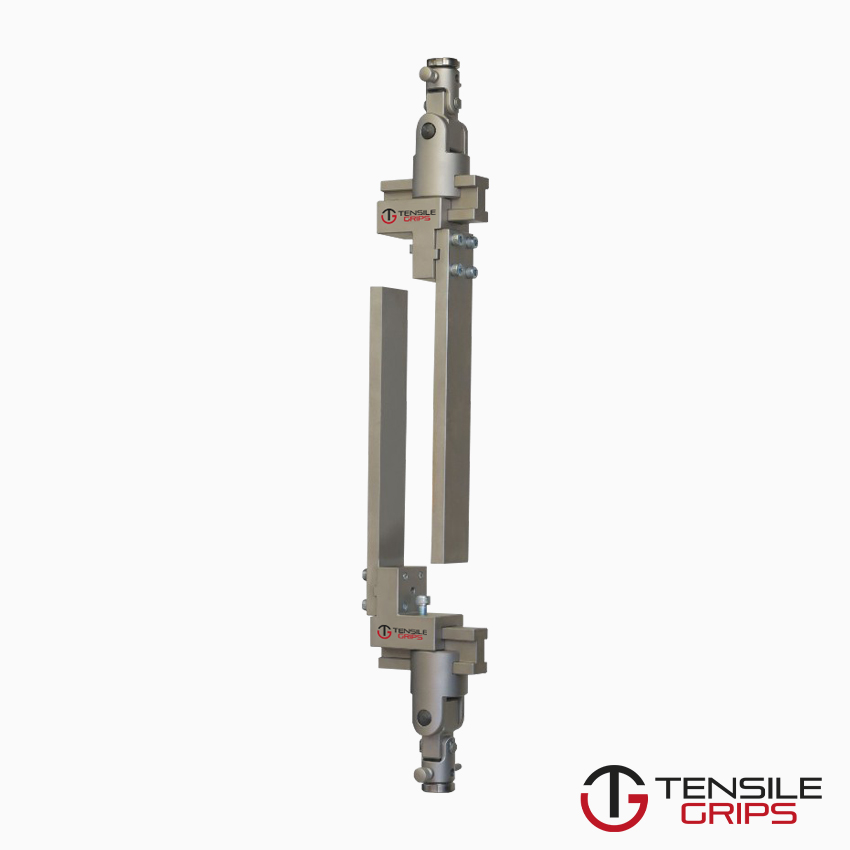

The two ends of the shear fixture push or pull parallel to the sandwich facings to create shear stress.

The goal of the test is to cause a 100% shear failure of the sandwich core.

Any adhesive failures that are seen between the sandwich panels and core, or the sandwich panels and loading plates, should be discarded and not included

in the final data analysis.

ASTM C273 – Significance and Use

The core shear properties are fundamental properties that are used in the design of sandwich panels.

This test method provides information on the load-deflection behavior of sandwich constructions or cores when loaded in shear parallel to the plane of the facings.

From a complete load-deflection curve, it is possible to compute core shear stress at any load (such as the shear stress at proportional limit, at yield, or

at maximum load) and to compute an effective core shear modulus.

The test does not produce pure shear, but the specimen length is prescribed so that secondary stresses have a minimum effect.

Approximate shear properties can also be obtained from a sandwich flexure test (see Test Method C 393).

This test method provides a standard method of obtaining sandwich core shear data for quality control, acceptance specification testing, sandwich design, and

research and development.

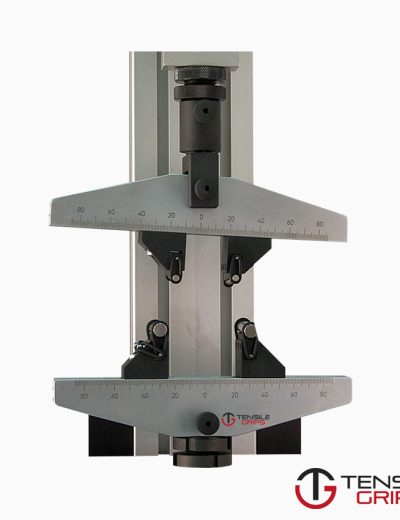

ASTM C273 – Geometry

The thickness of the sandwich specimen being tested can vary and is based on the thickness of the sandwich that is to be used in the field.

The width of the sample should be over two inches and the length should be over 24 inches in a 12:1 ratio unless otherwise agreed upon.

The direction of the loading force should be such that the loading plane intersects two diagonally opposite corners of the specimen.

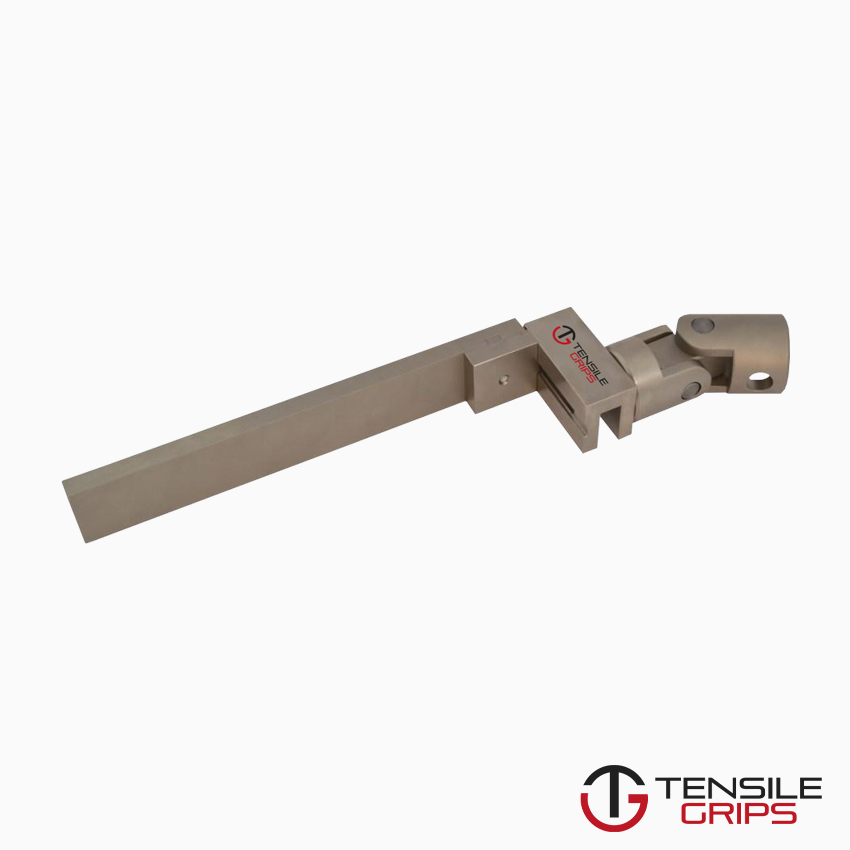

ASTM C273 – Solution

The ASTM C273 shear fixture is designed specifically for testing shear in both tension and compression.

The fixture has a swivel joint which allows the apparatus to self-align during the test.

The sandwich panels can be bonded directly to the fixture, or there is a small step that juts out and can support the sample when performing the test in compression.

A contact strain gauge is sometimes used for this test, however that is not very common.

ASTM C273 – Analysis

Shear Stress is calculated using a formula supplied in the official ASTM publication.

The shear modulus can also be calculated in a similar fashion and is a function of the load, slope of the deflection curve, displacement of the loading plates, and

the thickness of the core.

The max load is also a commonly recorded and simple test result.

Referenced Documents

ASTM Standards

ASTM C271/C271M Test Method for Density of Sandwich Core Materials

ASTM C393 Test Method for Core Shear Properties of Sandwich Constructions by Beam Flexure

ASTM D792 Test Methods for Density and Specific Gravity (Relative Density) of Plastics by Displacement

ASTM D883 Terminology Relating to Plastics

ASTM D2584 Test Method for Ignition Loss of Cured Reinforced Resins

ASTM D2734 Test Methods for Void Content of Reinforced Plastics

ASTM D3171 Test Methods for Constituent Content of Composite Materials

ASTM D3878 Terminology for Composite Materials

ASTM D5229/D5229M Test Method for Moisture Absorption Properties and Equilibrium Conditioning of Polymer Matrix Composite Materials

ASTM D5687/D5687M Guide for Preparation of Flat Composite Panels with Processing Guidelines for Specimen Preparation

ASTM D5961/D5961M Test Method for Bearing Response of Polymer Matrix Composite Laminates

ASTM E4 Practices for Force Verification of Testing Machines

ASTM E6 Terminology Relating to Methods of Mechanical Testing

ASTM E122 Practice for Calculating Sample Size to Estimate, With Specified Precision, the Average for a Characteristic of a Lot or Process

ASTM E177 Practice for Use of the Terms Precision and Bias in ASTM Test Methods