ASTM B533 Standard Test Method for Peel Strength of Metal Electroplated Plastics

ASTM B533 gives two procedures for measuring the force required to peel a metallic coating from a plastic substrate.

One procedure (Procedure A) utilizes a universal testing machine and yields reproducible measurements that can be used in research and development,

in quality control and product acceptance, in the description of material and process characteristics, and in communications.

The other procedure (Procedure B) utilizes an indicating force instrument that is less accurate and that is sensitive to operator technique.

It is suitable for process control use.

The tests are performed on standard molded plaques.

This method does not cover the testing of production electroplated parts.

The tests do not necessarily measure the adhesion of a metallic coating to a plastic substrate because in properly prepared test specimens, separation usually

occurs in the plastic just beneath the coating-substrate interface rather than at the interface.

It does, however, reflect the degree that the process is controlled

ASTM B533 / Apparatus

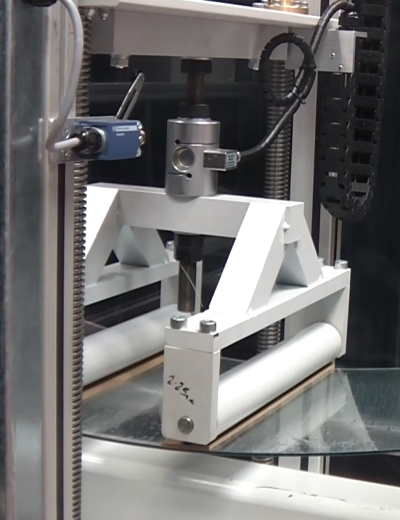

Procedure A

A tension testing machine that has selfaligning grips and that has a loading range that includes the forces to be measured, 5 to 200 N, shall be used to separate

the coating from the substrate, and measure the force required.

The machine shall meet the verification requirements of Practices

The speed of separation of the crossarms of the machine shall be adjusted to give a separation rate of 25 6 3 mm/min.

The machine shall automatically and continuously record on a chart the load on one coordinate and the amount of peel on the other coordinate.

The amount of peel may be obtained from calculation, using a known chart speed.

Procedure B

A spring-loaded, force-indicating instrument with a measurement range that includes the force to be measured, 5 to 200 N, shall be used to measure the force

required to separate the coating.

The indicated force shall be accurate to 610 %.

ASTM B533 / Procedure

ASTM B533 Procedure A

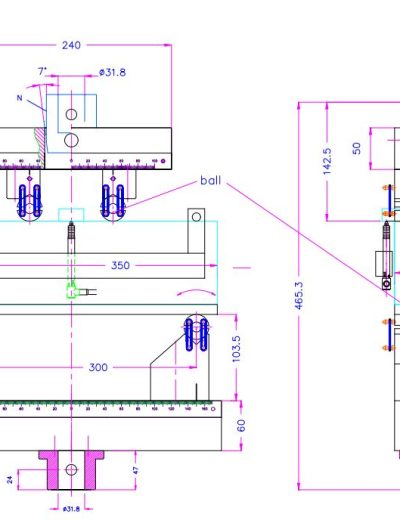

Install a holding fixture on the fixed arm of the testing machine.

The fixture shall support the plaque at a right angle to the pull direction of the machine.

Place the plaque in the holding fixture with the tab end facing out.

Locate the plaque so that the strip to be tested is centered over the centerline of the fixture.

Clamp the tab in the jaws of the movable crossarm of the testing machine.

Separate the strip from the plaque at a speed of 25 6 3 mm/min, and continuously record the force.

Repeat the test using the other strip on the plaque.

If a strip tears during separation, discontinue the test.

The readings obtained up to the point of tearing may be used if at least 25 mm of the strip were separated before the tear.

ASTM B533 Procedure B

Restrain the plaque in a way that permits separating the strip.

Attach the tab to the spring-loaded tester.

Separate the strip from the plaque at an angle of 90 6 5° to the plaque and at a rate of 25 6 3 mm/min.

During the separation the force on the indicator will rise to peak values and fall back. Record the peak values.

Repeat the test using the other strip on the plaque.

If a strip tears during separation, discontinue the test.

The readings obtained up to the point of tearing may be used if at least 25 mm of the strip were peeled before the tear.

Repeat the peel test with a second plaque.

Examine the underside of the peeled strip and the bared area of the plaque and determine whether the separation occurred in the surface layers of the plaque

(cohesive failure) or at the interface (adhesive failure).

Plastic adhering to the underside of the strip is not always apparent to the naked eye, and therefore should be verified microscopically.

Remove any plastic from the strip by means of a suitable solvent.

Acetone, for example, will remove ABS.

Measure the thickness of the strip in several locations using a ball micrometer that can be read to the nearest 1 µm.

(A micrometer that reads in inches may be used if it can be read to the nearest 0.0001 in., 0.0001 in. = 2.5 µm.)

*** Before conducting ASTM B533 , it is important to read the entire specification. Standards can be obtained from appropriate standard authorities.