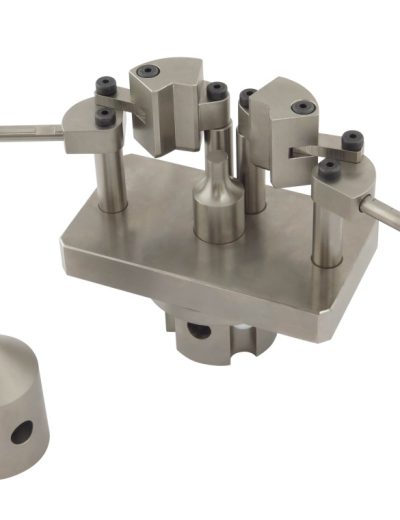

ASTM A125 Test Fixture

ASTM A125 – This specification covers hot-coiled, heat-treated helical compression springs with tapered, closed, squared and ground ends made of

hot-wrought round steel bars 3/8 in. (9.5 mm) and larger in diameter.

Please Contact With Us For More Information

ASTM A125 – Standard Specification for Steel Springs, Helical, Heat-Treated

ASTM A125 Helical Spring Testing

ASTM A125 – This specification covers hot-coiled, heat-treated helical compression springs with tapered, closed, squared and ground ends made of

hot-wrought round steel bars 3/8 in. (9.5 mm) and larger in diameter.

This specification also serves to inform the user of practical manufacturing limits, mechanical tests, and inspection requirements applicable to the type of spring

ASTM A125 covers spring compression testing for helical heat-treated springs.

These types of springs are typically used in the transportation industry for suspension systems and can also be seen in certain types of industrial machinery.

Springs are often used to store or dissipate energy in a simple and efficient manner.

Most spring testing is done in the compression mode.

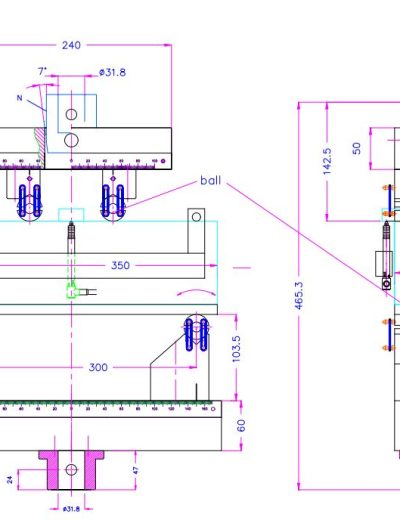

Geometry

Springs are manufactured in many different varieties.

Some key measurement characteristics include the diameter of the bar, the height of spring, the number of coils as it relates to height, coil diameter, and whether

the end of the spring is squared or round.

ASTM A125 specifies a deflection loading of up to 85% of the original height.

There are several calculations cited under A125.

Solid Capacity is represented in lbs. and is a measure of the capacity of the spring to withstand and store a compressive force.

The solid height is defined as the total height of the spring when it is subjected to a compressive load that causes all adjacent coils to touch.

Once all of the coils touch, the spring cannot be compressed any farther, therefore solid height is a maximum value.

Similar Specifications

ASTM A230

ASTM A313

ASTM B593